www.industryemea.com

04

'25

Written on Modified on

Voith completes dual FATs for Snowy 2.0 components across continents

FATs in Shanghai and Heidenheim validated rotor poles, stator bars, and governors for Units 2, 4, 5, 6, ensuring precision integration.

voith.com

Voith has successfully completed two major Factory Acceptance Tests (FATs) for the large-scale pumped storage project Snowy 2.0 – nearly simultaneously and across two continents. Generator key components (U4 rotor pole and U2 stator bar) were accepted at the Voith facility in Shanghai, while digital and hydraulic governors for Units 5 and 6 passed final FATs in Heidenheim. Both FATs were completed on schedule and received positive feedback from the customer.

Shanghai: Generator components meet exacting standards

In Voith’s Shanghai workshop, FATs focused on critical generator parts: the rotor poles for Unit 4 and stator bars for Unit 2. The components met all technical specifications. The rotor poles demonstrated uniform magnetic flux density, high-quality lamination, and precise winding, while the stator bars showed consistent insulation thickness, excellent partial discharge values, and precise bar end shaping.

The complete FAT process – from raw material inspection to final testing –was conducted under a structured, traceable quality framework. According to customer feedback, the process reflected a high level of manufacturing discipline and effective quality management.

Heidenheim: Smart automation and team training in one

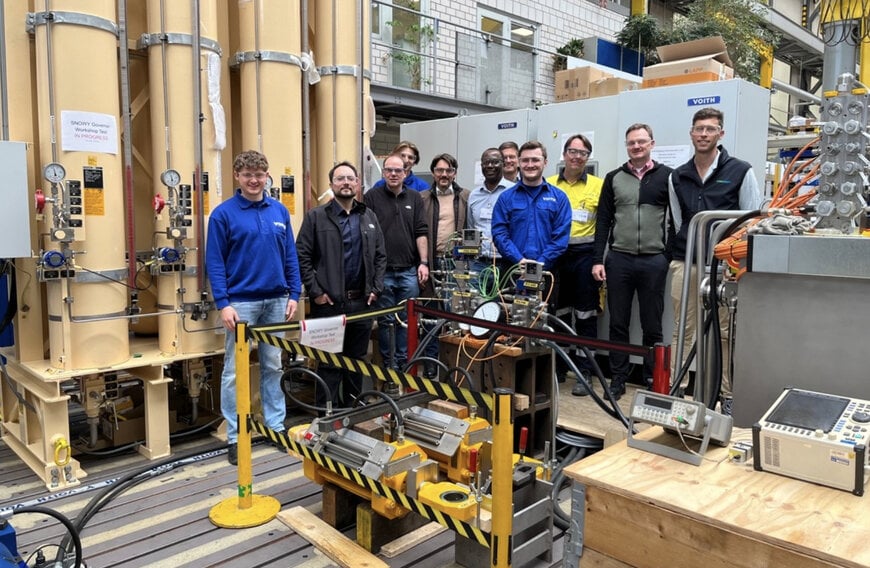

At Voith’s Heidenheim location, the Automation team conducted integrated FATs for Units 5 (asynchronous) and 6 (synchronous). These tests included both the digital and hydraulic governors, assembled and tested in their final cabinet configuration with live connections to the control system.

The FATs marked the first implementation of bus-controlled proportional valves on an Allen-Bradley PLC platform. After initial system calibration, all functions ran as intended. Opening and closing times of the hydraulic system were optimized in preparation for faster commissioning at site. The emergency shutdown sequence, including asynchronous valve closure, was executed in accordance with the project’s specifications.

More than 30 engineers and technicians from the Automation team participated, using the FAT to build hands-on experience that will support upcoming field activities in Australia. This process contributed to internal knowledge transfer and improved readiness for on-site commissioning.

Global teamwork sets the tone for next project phase

With the successful completion of these key FATs, Voith is well positioned for the next project phase in Australia. The coordinated effort between regions and functions once again confirms Voith’s global integration strength and commitment to quality on major infrastructure projects.

www.voith.com