Voith supports start-up of recycled containerboard machine in Duino

Mondi commissions new recycled containerboard paper machine in Italy with Voith supplying full-line technology from stock preparation to winding.

voith.com

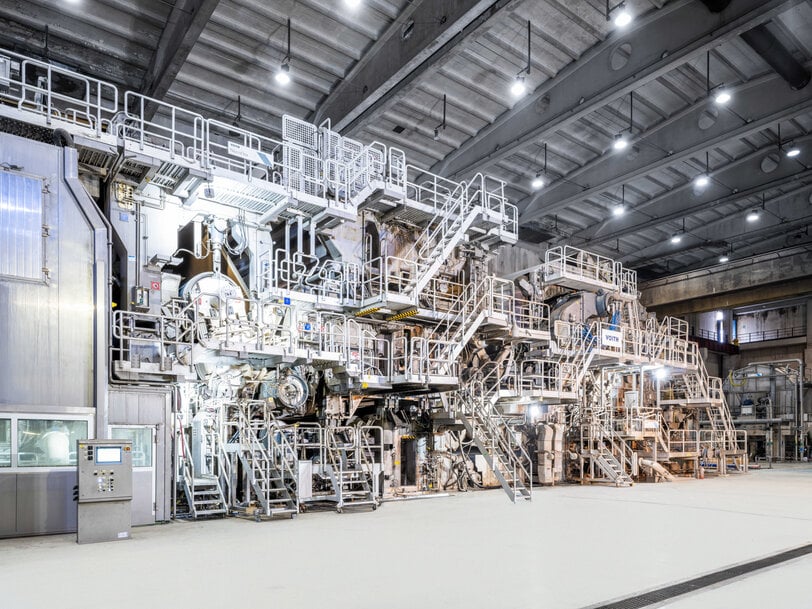

Mondi has successfully brought a new recycled containerboard paper machine online at its Duino mill in Italy, supported by Voith as full-line supplier. The machine was commissioned on schedule and is designed to produce up to 420,000 tonnes of recycled containerboard per year once fully ramped up, strengthening Mondi’s production capacity for sustainable packaging grades in Europe.

Integrated process design for recycled containerboard production

The new installation is Mondi’s widest recycled paper machine and produces waste-based fluting starting at 80 gsm, testliner from 90 gsm, and paper reels with widths ranging from 0.95 m to 3.35 m. Voith’s scope of supply covered the entire process chain, from stock preparation through the paper machine to the winder section, complemented by service agreements and a clothing package.

Voith implemented a BlueLine stock preparation system designed to deliver stable stock quality with optimized fiber yield and reduced energy consumption. An IntensaPulper combined with a TwinPulp detrashing system ensures efficient pulping, while the InfiltraDisc filter improves drainage performance and consistency control.

Rebuild and modernization of paper machine technology

As part of the project, the existing machine was converted into an XcelLine paper machine configuration. Key components include a MasterJet Pro headbox, a DuoFormer CBv shoe-blade former, and a DuoCentri NipcoFlex press, all aimed at supporting high productivity and consistent paper properties. Film application is handled by a SpeedSizer AT, while winding is performed using a MasterReel system.

The existing VariTop winder was rebuilt to accommodate containerboard grades, contributing to higher efficiency and improved productivity across the line.

Automation and quality control integration

To support stable operation and product quality, Voith supplied and installed its OnControl automation system, including distributed control (DCS) and machine control (MCS). Quality monitoring is handled by the OnQuality quality control system with ModuleJet, ModuleSteam, and ModulePro actuators, as well as scanners for basis weight and moisture measurement. The OnView information system provides process transparency and supports data-driven optimization of production.

Collaboration and operational outcomes

The project demonstrates a coordinated approach to mill modernization, reducing interface complexity through a single full-line supplier. According to Mondi, this contributed to punctual commissioning and efficient project execution. Voith will continue to support the Duino mill during the ramp-up phase to further optimize performance and fully utilize the capabilities of the new installation.

The Duino start-up reflects a broader industry trend toward high-efficiency recycled containerboard production, combining resource efficiency, advanced automation, and scalable machine concepts to meet growing demand for sustainable packaging materials.

www.voith.com