Bosch Rexroth at the LogiMAT: Modular automation for mobile robots

Robotic and automation components from Bosch Rexroth simplify and accelerate the development and commissioning of automated guided vehicle systems.

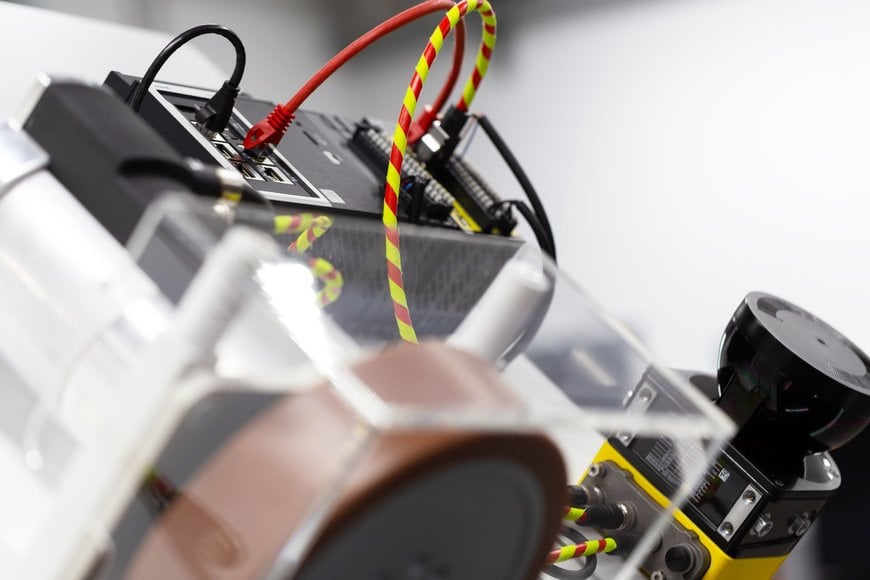

The Robotics Kit ROKIT and the automation toolkit ctrlX AUTOMATION from Bosch Rexroth simplify and accelerate the development and commissioning of automated guided vehicles.

- Modular software and hardware solutions for easy integration in industrial mobile robots

- Open standards and interfaces provide high degree of freedom

- Less development work and shorter time to market

When it comes to the automation of mobile robots, Bosch Rexroth is embracing modular software and hardware solutions. This provides manufacturers and system integrators with utmost freedom on different levels, ranging from the functional expansion of individual vehicles to central fleet and device management. They can flexibly combine the necessary components from robotics and automation to suit their own individual needs and thereby benefit from minimal integration work.

According to market research conducted by the International Federation of Robotics, transport and logistics represent the top applications for automated guided vehicles and autonomous mobile robots, and these areas are experiencing very high growth rates. It is no surprise, therefore, to see both established companies and start-ups feverishly working on new concepts. With ROKIT – The Robotics Kit and the automation toolkit ctrlX AUTOMATION, Bosch Rexroth provides manufacturers and system integrators with modular, highly flexible solutions that allow them to bring their expertise to life, develop at a rapid pace and thus set themselves apart from the competition.

Easy automation without expert knowledge

The modular toolkit ROKIT includes software and hardware components to facilitate the autonomous operation of a wide range of vehicle architectures. As an open system solution, the modules integrate seamlessly into higher-level control systems and are compatible with established industrial PCs, operating systems, and laser scanners. The localization software ROKIT Locator determines the vehicle position in real time and automatically produces maps of the surroundings – without the need for any structural measures.

The ROKIT products are controllable and linkable via an open user interface (API). The graphical user interface aXessor is now part of the ROKIT package by default and with full functionality. With its intuitive perspectives, this central management interface serves as a quick and transparent means of conducting rapid engineering as well as commissioning, operating, and servicing the vehicles. And all this can be accomplished without any expert knowledge. The laser-based localization software ROKIT Locator determines the vehicle position in real time and automatically produces maps of the surroundings – without the need for any structural measures.

The motion planning software ROKIT Navigator is used to control the movement of mobile robots. As a 6-in-1 wheel drive module, the ROKIT Motor includes the wheel, gearbox, brake, motor, functional safety encoder and controller, thus serving as a perfectly coordinated group of components tailored to the performance profile of automated guided vehicles and autonomous mobile robots. The use of Fail Safe over EtherCAT (FSoE) communication reduces the amount of wiring required and ensures the necessary safety of the mobile robot.

Modular software and hardware solutions provide manufacturers and system integrators with utmost freedom on different levels, ranging from the functional expansion of individual vehicles to central fleet and device management.

One control system for all tasks

The control platform ctrlX CORE combines all tasks that were previously distributed across PCs, PLCs and safety controls. This allows developers to reduce the number of components and thus the necessary installation space. At the same time, the amount of wiring required is reduced due to the functional integration and use of modern communication interfaces. The automation toolkit ctrlX AUTOMATION is based entirely on open standards such as EtherCAT, OPC UA, MQTT or VDA 5050. The ctrlX Data Layer ensures rapid, error-free data exchange between process and safety functions. All safety information is exchanged via an FSoE connection. Manufacturers can thus attain functional safety corresponding to performance level d with minimal effort. To this end, the ctrlX SAFETY from Bosch Rexroth provides all the necessary interfaces and modules. As well as the standard functions, it is also possible to perform safe arithmetic calculations.

Robotics tasks for AMRs such as additional manipulators are implemented by the integrated motion control. By connecting additional sensors and actuators, further functions can be integrated, such as automatic opening of roller shutters or communication with other peripheral units.

Central device management for updates

The ctrlX CORE is based on a Linux operating system and app technology. Developers can select from numerous Bosch Rexroth apps, make use of third-party apps or create their own. Even after delivery, updates or additional apps can be installed both quickly and easily. For this purpose, ctrlX AUTOMATION supports central fleet management via the ctrlX Device Portal, which enables remote management of all vehicles within a fleet.

Developers can integrate the various components of the robotics kit ROKIT and the automation tookit ctrlX AUTOMATION into their concepts on an incremental basis. Engineering tools combined with the consistent modularity and openness of the components significantly reduce the development effort and, consequently, the time to market for automated guided vehicle systems and autonomous mobile robots.

www.boschrexroth.com