www.industryemea.com

01

'22

Written on Modified on

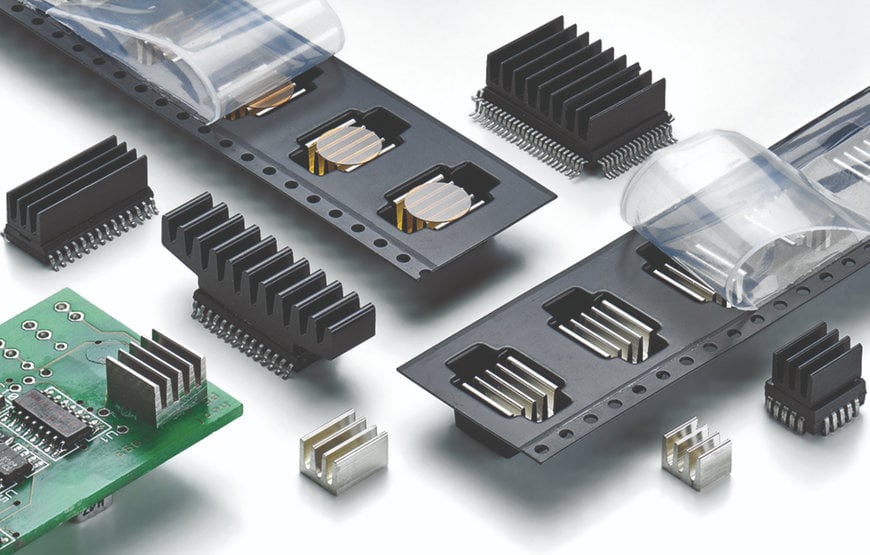

SMD HEATSINKS ON TAPE & REEL

The demands for efficient heat dissipation of electronic devices on the PCB have not been reduced. The increased complexity of the assemblies, as well as the combination of individual functional modules into one component, lead to an unwelcome and, in the long run, harmful power loss on the PCB, which is directly converted into heat.

However, too much heat does not only damage the electronic devices on the PCB, but can also affect solder joints and the PCB material itself in the long term. Therefore, the use of heatsinks is essential and indispensable for multiple applications on the PCB. Especially for these applications, Fischer Elektronik offers extremely efficient SMD heatsinks of the ICK SMD ... series, in future various types also in tape & reel design.

SMD heatsinks are made of a highly thermally conductive aluminium alloy and are manufactured using an extrusion process. The respective heatsink geometry as well as its weight are adapted for surface mounting on circuit boards. The smallest SMD heatsink that can be manufactured using the extrusion process has a contact surface of just 31.5 mm², which corresponds to a weight of 0.24 g. Due to the very low weight of the SMD heatsinks, direct mounting on the device surface is also possible without damaging the soldering of the device on the PCB through mechanical stress. The SMD heatsinks are offered in black anodised and solderable tin-plated surface finishes.

The black anodised heatsinks are mounted on the device using double-sided adhesive heat-conducting foils or 2-component epoxy resin heat-conducting adhesives. In contrast, SMD heatsinks with a solderable surface coating can be applied directly to the PCB, or more precisely said to an existing copper heat spreader surface that is connected to the device to be cooled, by means of reflow or wave soldering. Solderable SMD heatsinks offer an additional serious advantage through simple integration into the assembly and soldering process of the PCB. Due to standard packaging forms, such as tape & reel, the SMD heatssink can be processed and handled like any other device.

The position of the SMD heatsink in the tape, the tape diameter as well as the tape width are designed according to individual customer specifications. Depending on the type and functions of the pick and place machine, the individual heatsinks can also be provided with a pick and place aid on the fin side, a glued-on capton dot. This makes it possible to suck in the SMD heatsink on the fin side without rotation and to place it on the PCB with the bottom surface facing downwards.

www.fischerelektronik.de