www.industryemea.com

21

'22

Written on Modified on

Vanzetti Engineering participates at Gastech

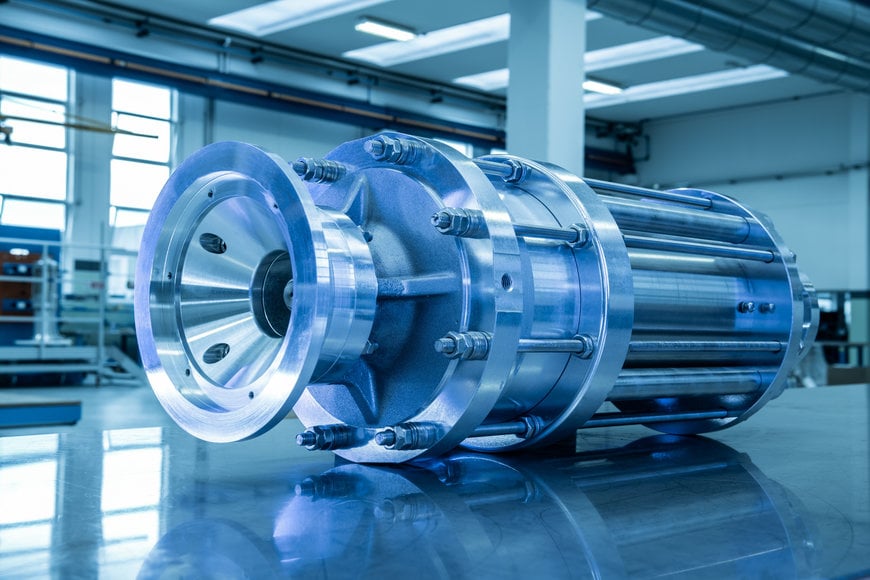

Vanzetti Engineering will participate at Gastech 2022 (Fiera Milano, 5-8 September 2022), stand 13D21, with its range of ARTIKA series submerged cryogenic pumps for LNG.

Vanzetti Engineering will participate at Gastech 2022, the international trade fair for the gas, LNG, hydrogen and energy sectors scheduled to take place in Milan from 5 to 8 September.

Vanzetti Engineering will exhibit its ARTIKA series submerged cryogenic pumps for liquefied natural gas at stand 13D21. The models on show will range from the smallest ARTIKA 120-3S to the largest ARTIKA 300-2S and will include the prototype of the new single stage ARTIKA 400 pump, which is currently under development. With a flow rate of up to 546 m3/h, the ARTIKA 400 will complete the current range of submerged LNG pumps designed by Vanzetti Engineering.

The features of ARTIKA pumps include the seal-less concept with the motor bearings permanently lubricated by liquefied natural gas, which allows a permanent cold condition for quick and efficient starting and stopping and a low maintenance frequency due to the absence of wear parts.

The ARTIKA series submerged cryogenic pumps for liquefied natural gas are available in one-stage or multi-stage configurations (2, 3, 4 or 6). They are designed to work submerged in cryostats/sumps or in cryogenic tanks and are suitable for continuous and discontinuous operations. They feature helical inducers to minimize NPSH requirements, integrated motors to be used with inverter/VFD LPG and low noise (< 80dB) during operations.

ARTIKA submerged pumps are designed to supply LNG at different flow rates and pressures. For example, for automotive sector LNG refuelling stations, Vanzetti Engineering proposes the ARTIKA 160 submerged pump that can be used for one or two LNG dispensers.

The ARTIKA 120-3S is the smallest pump in the series and is used in marine sector applications.

The ARTIKA 200-4S can deliver a guaranteed flow rate of over 30 m3/h at 35 bar, while the ARTIKA 200-6S is even able to reach a differential pressure of 55 bar. Both models can be used in marine sector applications for FSRU (Floating Storage Regasification Units) projects.

In order to meet the needs of applications that transfer liquefied natural gas to small and medium size terminals, the ARKITA 300 is available in a 1 or 2 stage configuration, which can reach a flow rate of up to 270 m3/h.

www.vanzettiengineering.com