Comprehensive expertise in steel and plastic. KABELSCHLEPP cable and hose carrier systems take every detail into account in a project that is unique worldwide

Manufacturers of machine tools and systems require a huge number of components for their designs. In particularly demanding or complex applications, suppliers have to provide not only the appropriate products, but also know-how and development expertise. One reason why MT Mechatronics had no alternative to working together with KABELSCHLEPP on this truly superlative project.

Manufacturers of machine tools and systems require a huge number of components for their designs. In particularly demanding or complex applications, suppliers have to provide not only the appropriate products, but also know-how and development expertise. One reason why MT Mechatronics had no alternative to working together with KABELSCHLEPP on this truly superlative project.

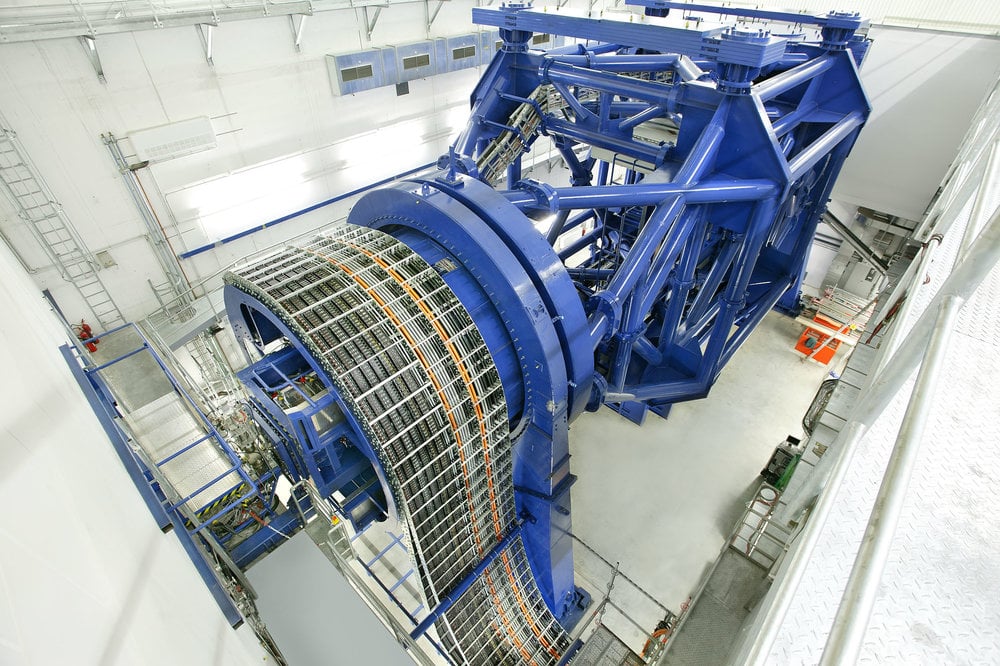

The Heidelberg Ion Beam Therapy Center (HIT) for cancer treatment at the Heidelberg University Hospital is a partially below-ground high-tech system on three stories covering almost the area of a soccer field, in which heavy ions are accelerated to three-quarters of the speed of light and then guided precisely into the tumor. The HIT has a number of characteristics that make it unique worldwide at present. One of them is the gantry, the high-precision rotating beam guidance system for heavy ions: This colossus is three stories tall, and has an overall weight of 670 metric tons; 600 of which is movable.

The emphasis was on pointing accuracy of the beam guidance, and the adjustment speed. In the end a cable and hose weight of 150 kg/m and moments of up to 15,000 Nm had to be accommodated.

Heavy mechanical loads, radiant heat of in some cases over 70 °C, extremely limited installation space, diameters of the cables and hoses from 5 mm to 42.5 mm. These include, for example, everything from thin control cables to thick water cooling hoses. The diameters and numbers of cables and hose were changed right up to the last day – reserves had to be provided. For reasons of space and the specific situation, a rotary arrangement was not possible.

KABELSCHLEPP provided a space-saving solution with two steel carriers, one inside the other, combined with a reverse bending radius. The gantry is now operated with a 15.25 meter long steel carrier of the type S 2500 in a 4-band design with an empty weight of 1,375 kg. Saddled on top of this is a smaller, 14.58 meter long carrier of the type 1800, likewise in a 4-band design, with a bend radius and a reverse bend radius of 1,750 mm and an empty weight of 732 kg. So that the two steel carriers glide on each other exactly, the chain bands were fitted with guide plates. The two carriers have play relative to each other both in motion and at rest.

For the cables with low flexural rigidity and small diameters, additional plastic carriers of the MONO and UNIFLEX series were used; these rest inside the steel carriers.

Advantages:

1. Always the right carrier, whether of steel, plastic, or plastic combined with aluminum.

2. Steel carriers are radiation-resistant in the long term, and are suitable for heavy mechanical loads

3. Steel carriers are suitable for high additional loads, in this case 150 kg/m

4. Space-saving solution through 4-band carriers, one inside the other, with built-in plastic carriers for cables with small diameters

5. The aluminum stays used provide clear advantages, such as stability and low friction on the cable cladding. This is especially important when one considers that the power cables are also cooled with water. Damage to the insulation could in some cases lead to a total failure of the system.

Captions:

Riding piggyback: Saddled on top of a steel carrier in a 4-band design is a smaller carrier in order to be able to accommodate all of the cables and hoses with the application-specific maximum possible carrier width

Thanks to the elaborate gantry construction "behind the scenes", the radiation can be guided towards the patient from different directions to achieve the optimal treatment angle