MAXXMILL 750: New Compact Vertical Milling Centre for 5-Sided Machining

Based on its long-standing experience and customer-oriented philosophy, EMCO – in cooperation with the Italian subsidiary EMCO Famup – has expanded its MAXXMILL series and developed a high-performance vertical CNC milling centre for 5-sided machining: the new MAXXMILL 750. The compact and optimised machine structures as well as the technical adaptations enable users to machine complex and heavy workpieces with an edge length of 530 x 530 x 417 mm in just one setting - with efficient results in terms of surface quality and precision.

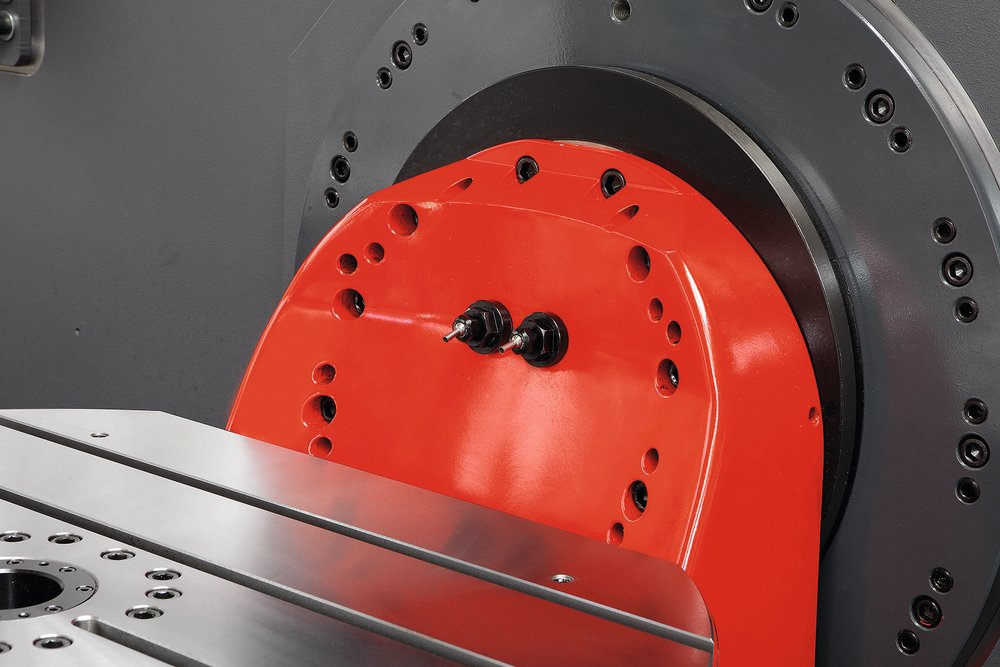

Maxxmill 750: Vertical milling centre for the 5-sided machining

HALLEIN – TAXACH. True to the company commitment "Made in the Heart of Europe", based on its long-term experience in the production of vertical 5-sided machining milling centers and always in search of the best solutions to improve its products according to the customers' expectations, EMCO presents the new MAXXMILL 750, a machine that allows for 5-sided machining in just one setting while offering maximum precision, the latest control technology and smart structural solutions - and all of this at an outstanding price-performance ratio.

The machine structure is a perfect combination of cast iron and welded steel, which offers maximum stability and thermal symmetry.

Supported by roller guides with a diameter of 45 mm on the X- and Y-axes and a direct drive motor on the Z-axis, the long travels of 750 mm in X, 610 mm in Y and 500 mm in Z make it possible to produce milled parts with maximum dimensions of 530 x 530 x 410 mm in small or medium batch sizes, while ensuring high rigidity as well as optimum precision and excellent surface qualities on the workpiece. Thanks to an optionally available table front support, the workpiece weight can be increased to 500 kg.

Depending on the production requirements, a powerful mechanical spindle with a maximum speed of 12,000 rpm or a water-cooled motor spindle with a maximum speed of 15,000 rpm can be selected.

Despite the increased travel dimensions, the machine is compact and ergonomically designed. As the tool magazine holds 30 tool stations ready for use, complex machining processes can be carried out simply and efficiently. The user can personalise the tool magazine with a tool drum featuring 40 or 60 tool stations with ISO 40 and BT 40 tool holders. Besides, the motor spindle may also be acquired with a DIN69872 pull stud and HSK-A63. The machine’s footprint size remains unchanged.

Easy loading is guaranteed thanks to the large machine door. In order to be able to integrate intelligent solutions for automation systems, an automatic door may optionally be installed on the right side.

The work area is large and can easily be cleaned from swarf thanks to the hinge-type chip conveyer, chip flushing system or flushing system installed directly on the table, all of which are available as an option.

Due to the simple and free access to the areas concerned, maintenance works can be carried out straightforwardly.

The MAXXMILL 750 can be programmed using the latest control technology from either Siemens or Heidenhain. The control unit is attached to an ergonomic control panel that is inclined to the front and equipped with a rotary function. This solution guarantees optimum working conditions for the operator.

Naturally, EMCO's commitment "Made in the Heart of Europe" also applies to the MAXXMILL 750. The machines are completely developed and produced in Europe in cooperation with European brand manufacturers that meet the highest standards in terms of quality, productivity and efficiency.

The MAXXMILL 750 is therefore the ideal vertical milling centre for the 5-sided machining of parts in low or medium quantities. This makes it particularly suitable for contract manufacturers, industrial enterprises such as automotive supply companies, general mechanical manufacturing and higher-level training institutions.

Technical data:

Travels and tolerances

X-axis travel [mm] 750

Y-axis travel [mm] 610

Z-axis travel [mm] 500

Tilting range B-axis +/- 100°

Rotating range C-axis n x 360°

Rapid traverse X/Y/Z [m/min] 30

Table

Length x width [mm] 760 x 600

Max. work piece weight [kg] 300 (500)

Main Spindle (mechanical spindle)

Speed range [rpm] 50 – 12 000 (not continuous)

Spindle power [kW] 15

Torque [Nm] 100

Main Spindle (motor spindle)

Speed range [rpm] 50 - 15000

Spindle power [kW] 20

Torque [Nm] 100

Tool Magazine

Number of tool stations 30 (40/60)

Tool change time (tool - tool) [sec] 2

Max. tool diameter [mm] 80

Max. tool length [mm] 250

Max. tool weight [kg] 8

Chip flushing system installed directly on the table.

750 x 600 mm table; for workpieces with a maximum weight of 300 kg – an increase to 500 kg is possible with the optionally available table front support

Contact:

EMCO GmbH

Christa Vergnes,

e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Salzburger Strasse 80, Postfach, 5400 Hallein-Taxach AUSTRIA

Tel.: +43-6245-891-0, Fax: +43-6245-86965

Internet: www.emco-world.com