www.industryemea.com

28

'26

Written on Modified on

Electrical Condition Monitoring for Three-Phase Motors

Schaeffler expands its OPTIME ecosystem with electrical condition monitoring to detect motor faults and prevent unplanned downtime.

www.schaeffler.com

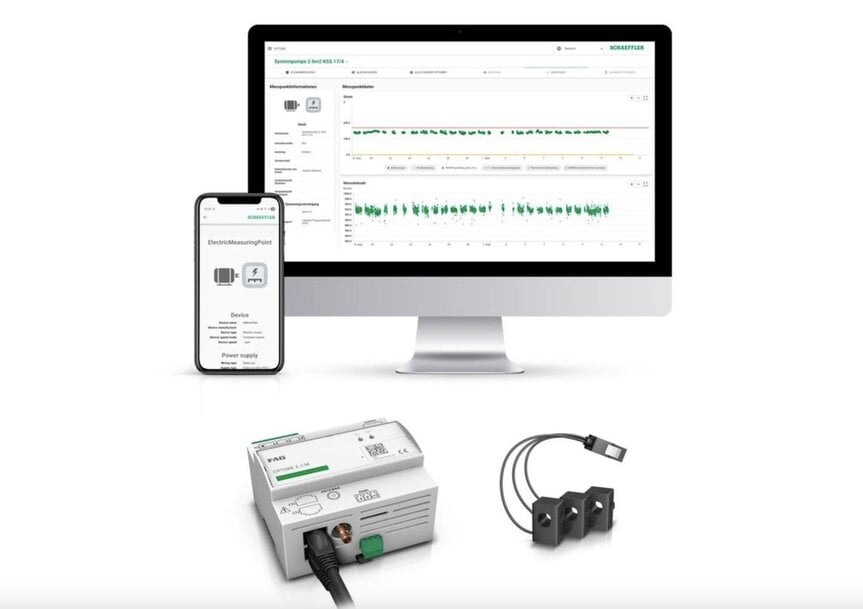

Schaeffler has extended its OPTIME condition monitoring ecosystem with FAG OPTIME E-CM, a solution designed to monitor the electrical condition of three-phase motors and complement existing vibration-based diagnostics in industrial environments.

Extending condition monitoring beyond mechanics

The OPTIME ecosystem combines sensor technology, cloud software, and Schaeffler’s bearing and application expertise to support predictive maintenance and smart lubrication. Until now, the focus has primarily been on vibration-based monitoring to identify mechanical wear and damage.

With the introduction of FAG OPTIME E-CM (Electrical Condition Monitoring), Schaeffler adds an electrical perspective to condition monitoring. The solution targets three-phase motors commonly used in compressors, pumps, fans, blowers, grinding machines, and other equipment found across most industrial sectors. By monitoring electrical parameters alongside mechanical behavior, maintenance teams gain a more complete picture of asset health.

Detecting electrical faults at an early stage

FAG OPTIME E-CM monitors and evaluates electrical currents and voltages of the motor drive. This enables early identification of a wide range of electrical issues, including insulation faults, cable defects, voltage fluctuations, overcurrents, broken rotor bars, and both static and dynamic eccentricity.

Electrical anomalies often develop before mechanical symptoms become visible. By detecting these deviations early, the system supports proactive maintenance planning, reduces the risk of unplanned shutdowns, and helps maintain stable production processes. This is particularly relevant in installations where motors operate continuously or are installed in large numbers.

Installation within the control cabinet

The system is designed for straightforward installation by qualified electrical personnel. It consists of a measuring unit and current sensors mounted directly in the control cabinet. Sensors are attached to the live motor cables, avoiding the need for direct access to the machine itself.

Depending on application requirements, either split-core current transformers or Rogowski coils can be used to measure current. Rogowski coils record the temporal change of current flow and are suited for a wide range of conductor sizes. The sensors can be positioned up to ten meters from the measuring unit and connected via cable. In addition, the three-phase voltage signals of the motor are connected directly to the unit.

This cabinet-based installation is particularly advantageous for motors in hard-to-reach or hazardous locations, as monitoring can be implemented without physical intervention at the machine.

Cloud-based analysis with AI support

Measured data is transmitted wirelessly via a secured LTE connection to the Schaeffler Cloud. There, the electrical signals are analyzed using algorithms that combine Schaeffler’s application know-how with machine learning and artificial intelligence techniques.

The analysis focuses on identifying patterns and deviations associated with developing faults. Based on these insights, the system generates condition assessments and maintenance recommendations that are made available to users through dashboards and mobile applications.

Integration into the OPTIME ecosystem

FAG OPTIME E-CM can be deployed as a standalone solution or integrated into an existing OPTIME setup that already includes vibration-based sensors. This modular approach allows operators to extend monitoring coverage incrementally, depending on asset criticality and maintenance strategy.

Maintenance managers receive automatic notifications when irregularities are detected and can use historical data to document asset behavior, refine maintenance intervals, and improve long-term reliability planning.

Application context

By combining mechanical and electrical condition monitoring, the OPTIME ecosystem addresses a broader range of failure modes in electric motor-driven systems. For industrial operators, this integrated approach supports higher plant availability, improved transparency of asset condition, and reduced maintenance costs—particularly in production environments where downtime carries significant operational and financial impact.

www.schaeffler.com