www.industryemea.com

10

'25

Written on Modified on

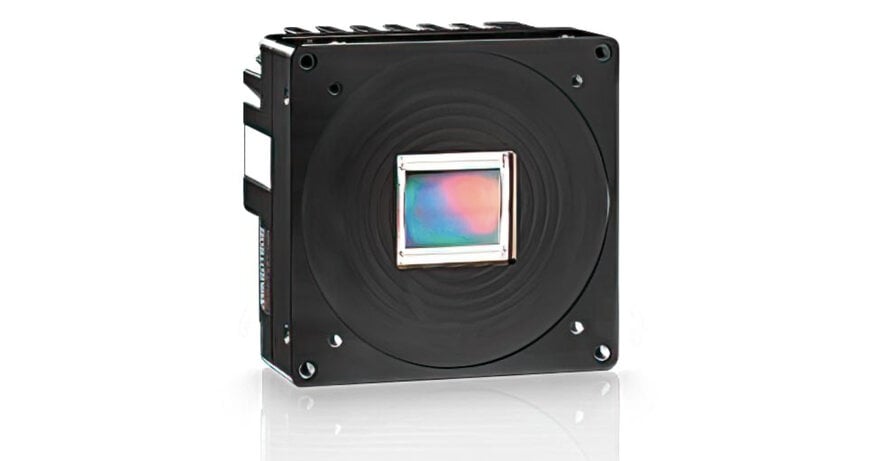

High-Speed Color Camera Enhances Precision Machine Vision

Mikrotron introduces a 21MP global-shutter model designed for demanding industrial imaging environments.

mikrotron.de

Industrial sectors such as electronics manufacturing, logistics automation, and precision quality control increasingly require imaging systems that combine high resolution with fast and stable data transfer. Addressing this need, Mikrotron released a new 21-megapixel color camera built to deliver detailed images at high frame rates while maintaining predictable performance in demanding machine vision environments.

High-Resolution Imaging for Fast Industrial Processes

The camera integrates a 21MP Gpixel CMOS global-shutter sensor capable of capturing 5120 × 4096-pixel images at 230 frames per second. This combination of resolution and speed is well suited to inspection tasks that must identify small defects under rising production throughput. For extremely fast processes such as web inspection, semiconductor packaging, and motion analysis, the camera can reach 5540 frames per second at 5120 × 128 pixels. The CoaXPress 2.0 interface supports up to 50 Gbit/s through one, two, or four lanes, enabling low latency and minimal jitter in synchronized or multi-camera systems.

Mechanical Stability for Vibration-Prone Environments

Mechanical design plays a critical role in imaging reliability in industrial settings. The camera uses a flat front lens mount that creates direct surface-to-surface contact between the housing and the lens. This minimizes sagging or rotation when using heavy optics or when the system is exposed to continuous vibration. Its compact 80 × 80 × 66 mm housing, IP30 rating, and resistance to shock and vibration allow integration into confined inspection stations and mobile equipment where mechanical stability is essential for consistent measurement.

Configurable Features for Diverse Machine Vision Workflows

To support variations in lighting, exposure, material reflectivity, and process speed, the camera provides several configuration options. Engineers can define specific image regions, select binning modes, adjust areas of interest, and compensate for shading or defective pixels. These tools help adapt the camera to workflows such as electronics assembly inspection, packaging verification, precision metrology, and motion analysis, where image quality depends on fine adjustments to acquisition parameters.

Positioning Within Existing Machine Vision Solutions

This model expands Mikrotron’s range by combining 21-megapixel resolution, 230-fps full-frame capture, and a CoaXPress 2.0 bandwidth of up to 50 Gbit/s. Competing solutions from manufacturers such as Basler, JAI, and Imperx offer comparable sensor sizes, but many operate at lower full-frame speeds or rely on interface standards with less available bandwidth. These differences influence real-time inspection performance when throughput and deterministic data transfer are key decision factors. The suitability of each alternative ultimately depends on interface compatibility, sensor architecture, and the environmental requirements of the installation.

Application Areas and Resulting Advantages

The camera’s performance profile makes it suitable for inspection tasks where both detail and speed are required. Automated optical inspection in electronics benefits from its high resolution when capturing dense circuit layouts or fine-pitch components. High-speed packaging and print inspection take advantage of frame-format flexibility to increase throughput. Semiconductor wafer inspection benefits from the mechanical stability of the flat-mount design and from the global-shutter sensor’s ability to avoid motion distortion. Motion analysis, robotics, and laboratory testing gain from predictable acquisition timing, which is critical in synchronized or real-time systems.

A Platform Aligned With Future Imaging Needs

By combining high pixel count, high-speed data transfer, and a vibration-resistant mechanical structure, this 21MP CoaXPress 2.0 model offers a solution aimed at inspection tasks requiring both high data volume and stable optical alignment. It strengthens Mikrotron’s machine vision portfolio and provides system integrators with a platform that balances pixel size, light sensitivity, dynamic range, and speed while supporting the reliability standards expected in automated production environments.

www.mikrotron.com