www.industryemea.com

03

'26

Written on Modified on

New terminal block series for future-ready control cabinets

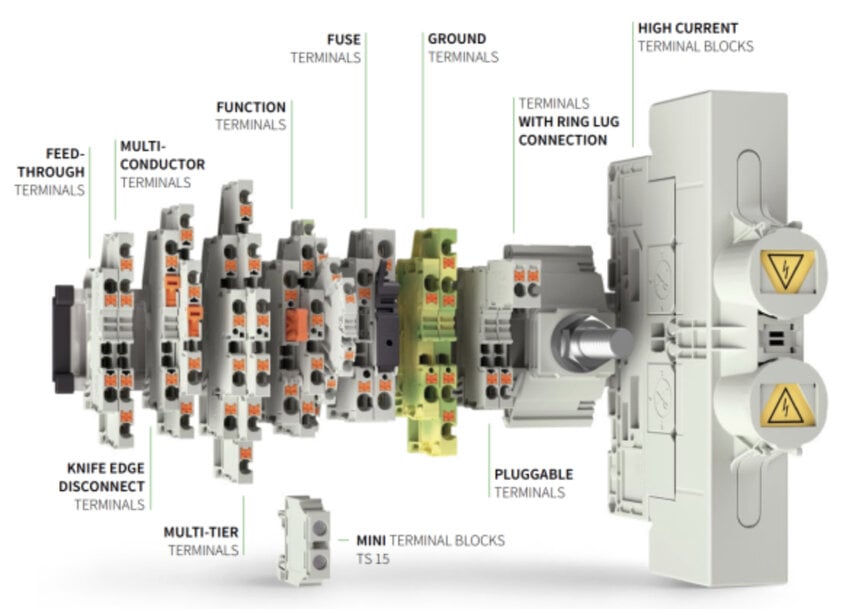

Wieland Electric introduces selos NEW GENERATION, a modular terminal block portfolio designed for efficient, sustainable industrial control cabinet construction.

www.wieland-electric.com

Wieland Electric has launched selos NEW GENERATION, a new terminal block series developed to address the growing requirements of industrial control cabinet construction. The portfolio combines proven connection technologies with new system and digital capabilities and includes terminal blocks, accessories, digital services, and planning and labeling solutions.

Technological context and market relevance

Control cabinet builders are facing increasing pressure from growing variant complexity, limited installation space, rising labor costs, and skilled labor shortages. Terminal blocks must therefore offer not only electrical reliability, but also ease of handling, compact design, and system compatibility. With selos NEW GENERATION, Wieland Electric responds to these challenges with a consistent system that integrates installation, planning, and documentation.

Connection technologies and handling

The series includes two connection variants. Selos WTPN terminal blocks with push-in technology enable fast, tool-free wiring of solid conductors and conductors with ferrules. The connection is vibration-resistant, maintenance-free, and provides consistently high contact force.

For applications with extended conductor requirements, selos WTN terminal blocks with screw connection are available. Their robust tension clamp design ensures high conductor compatibility and is suited for demanding industrial environments.

System accessories and space efficiency

A shared accessory system for both connection types reduces complexity in the control cabinet and simplifies inventory management. Multi-level terminal blocks and a housing design that is up to 66% more compact than conventional solutions support efficient use of available space and enable more compact control cabinet designs.

Digital support and project integration

To support engineering and manufacturing workflows, Wieland Electric provides digital tools such as selosPLAN, EPLAN data, and preconfigured terminal strips. These elements enable consistent project planning, error-free documentation, and integrated labeling. Seamless integration into existing engineering processes reduces manual effort and shortens project lead times.

Reliability and compliance

selos NEW GENERATION is designed for long service life and maintenance-free operation. All components and accessories are available ex stock and carry global certifications for international use. These features support high system availability and long-term investment security.

Sustainability and future readiness

The new terminal block series already complies with the requirements of the revised RoHS Directive 2027 and uses lead-free materials. Centralized warehousing, stable pricing structures, and long-term availability of technical documentation contribute to global supply security and long-term project planning.

Technical positioning

With selos NEW GENERATION, Wieland Electric positions a terminal block system that combines mechanical and electrical reliability with digitally supported processes. The combination of flexible connection technologies, reduced footprint, and integrated planning addresses key challenges in modern industrial and building automation control cabinets.

www.wieland-electric.com