How Furnace Inspections with IR Cameras Increase Efficiency, Improve Safety, and Reduce Costs

Furnaces play a critical role in refining and petrochemical operations, providing the high temperatures required for essential processes.

www.flir.com

When they fail, the consequences can be severe both in terms of safety and operational losses. A single day of unplanned downtime can result in losses exceeding $1 million. This is why companies like PROtect, under the leadership of Jason Czajkowski, are leveraging modern infrared (IR) technologies to conduct smarter, safer, and more cost-effective furnace inspections.

From Agema to G609: The Evolution of IR Furnace Cameras

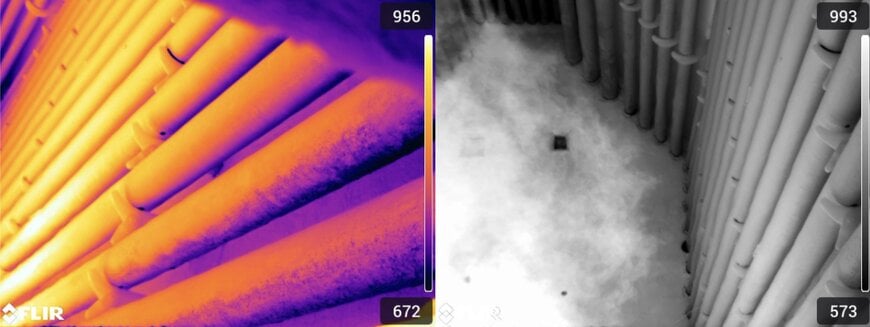

FLIR G609 High Resolution Furnace and Boiler Inspection Camera

IR technology in furnace inspections has evolved significantly over the past three decades. Early tools like the Agema 550 and Inframetrics 390 laid the groundwork for remote temperature diagnostics in extreme environments. These early cameras were bulky and required extensive setup but opened the door to non-contact thermal inspections. Later, FLIR’s GF309 became the workhorse of the industry, offering real-time thermal imaging through flames with improved ergonomics.

However, the GF309’s 320 × 240 resolution limited its ability to detect fine anomalies, especially at a distance. Czajkowski recognized the need for greater clarity and transitioned PROtect to the FLIR G609, which features a 640 × 480 detector. This allows PROtect technicians to detect smaller anomalies such as hot spots, coke buildup, or insulation breakdowns earlier and from safer distances.

Introducing the FLIR G609: A Smarter Tool for a Safer Job

The G609 represents the latest in FLIR’s IR camera evolution. It is built specifically for high-temperature applications and comes equipped with a re-engineered heat shield, factory-calibrated furnace lens, and a modern touchscreen interface. PROtect’s field teams report that the camera’s intuitive controls and robust design make it a reliable tool in even the harshest conditions.

With its increased resolution, the G609 can accurately measure temperatures on narrow furnace tubes deep within radiant sections something older models struggled with. "It’s not just clearer images," Czajkowski explains, "It’s better decisions, faster."

Complete Solutions: Pairing the G609 with Software for Maximum Impact

What truly transforms the inspection process is the integration of FLIR’s Thermal Studio Pro software. With the Route Creator tool, inspections are no longer reactive they’re pre-planned and executed with precision. Technicians follow a defined route with inspection points loaded into the camera, eliminating guesswork and ensuring consistency.

After inspections, images are automatically organized by inspection point, and reports are generated in minutes using professional templates. This saves countless hours of manual sorting and documentation, freeing up inspectors to focus on analysis and decision-making. According to Czajkowski, "This combination of camera and software creates a seamless workflow from planning to reporting."

Real-World Results: Safer Plants, Better Uptime

By adopting the G609 and an integrated software approach, PROtect has helped clients detect issues like burner misalignment and developing coking conditions early, preventing costly shutdowns. In one instance, early detection of a developing hot spot allowed a refinery to schedule a repair during planned downtime avoiding an emergency outage and saving hundreds of thousands in potential losses.

Conclusion

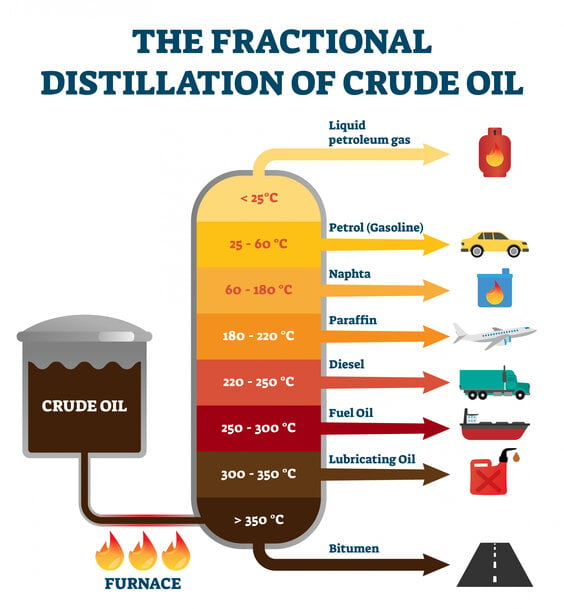

Illustration of the fractional distillation of crude oil

Infrared furnace inspections have matured from a specialty technique to an essential maintenance strategy. With modern tools like the FLIR G609 and expert leadership from professionals like Jason Czajkowski, PROtect is setting new standards for asset reliability. IR inspections now provide not only sharper thermal images but also fa faster workflows, greater safety, and measurable ROI. As Czajkowski affirms, "We’re not just taking pictures we’re delivering solutions that protect assets, budgets, and people."