www.industryemea.com

15

'23

Written on Modified on

PEPPERL+FUCHS FACTORY AUTOMATION: Innovative Technology Revolutionizes 3-D Measurement

Combination of Pulse Ranging Technology (PRT) with MEMS technology enables high-resolution 3-D point clouds.

From industrial automation to autonomous vehicles to care robots, mastering the challenges of the future will require powerful 3-D sensors that capture their surroundings quickly, comprehensively, and with millimeter precision. A technological innovation from Pepperl+Fuchs in cooperation with the Fraunhofer Institute for Silicon Technology ISIT enables maximum precision and performance - while remaining highly cost-efficient. For the first time, high-performance distance measurement technology is combined with MEMS technology. This forms the basis for the R3000 3-D LiDAR/MEMS sensor, which will be presented as a product study at the Hannover Messe 2023.

The R3000 3-D LiDAR/MEMS Sensor

The 3-D measurement is based on Pulse Ranging Technology (PRT), a distance measurement method developed by Pepperl+Fuchs that can be scaled to meet a wide range of requirements. Based on over 250,000 emitted laser pulses per second, it measures distances from a few centimeters to several hundred meters with millimeter accuracy. Ambient light and other environmental influences are effectively suppressed. As a result, PRT delivers fast, precise, and reliable measurement results.

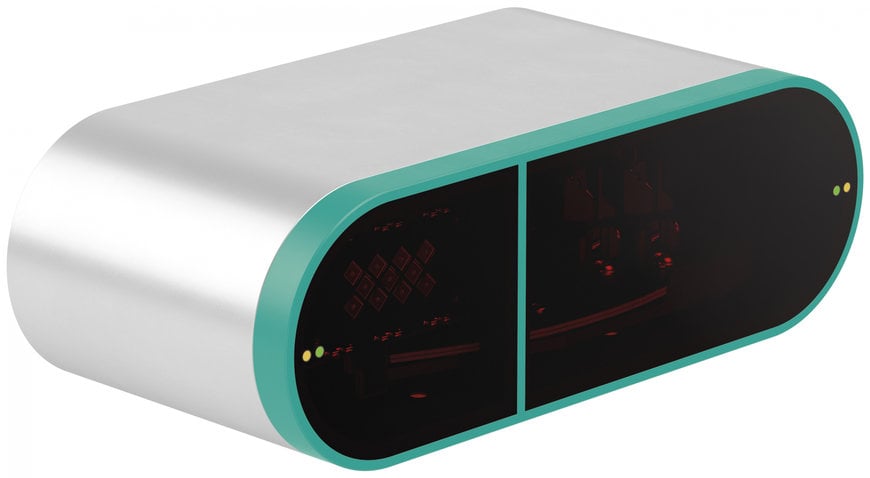

The compact and cost-effective R3000 enables high-performance 3-D measurement

To reach the third dimension, Pepperl+Fuchs combines PRT with a micro-electro-mechanical system from Fraunhofer ISIT for the first time as part of the R3000 product study: A small, economical, and mechanically robust MEMS mirror is integrated into the sensor.

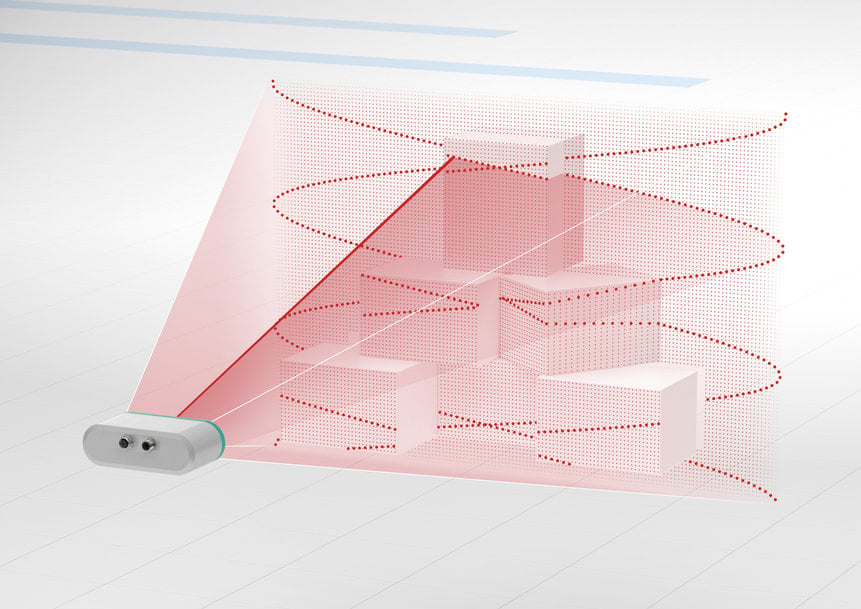

With the motion of the integrated MEMS mirror, the laser beam is deflected in two axes.

Through the motion of the piezoelectrically driven element, the emitted laser beam is deflected in two axes by 40° x 30°. Unlike conventional 3-D sensors, no pixel grid is created during the process of measurement. Instead, the R3000 uses a particularly small light spot and seamless scanning to produce ultra-high resolution 3-D point clouds with exceptional detail.

Intuitive Operation Due to Intelligent User Guidance

To make communication between man and machine as simple as possible, the R3000 is equipped with additional functions. The sensor not only generates a 3-D point cloud, but also a superimposed intensity image that can visualize the scene and therefore facilitate programming and operation. In addition, each measurement point can be displayed with a visible laser beam. The synchronous laser projector allows the R3000 to be precisely aligned and adjusted without additional tools, ensuring easy commissioning. This function also enables interaction between the user and the service robot, for example.

Due to precise scanning, ultra-high resolution 3-D point clouds are created.

Powerful 3-D Measurement for the Automation of the Future

With its innovative technology, the R3000 LiDAR/MEMS sensor will herald a revolution for solving complex automation tasks. Precise 3-D images of unknown environments are essential for the next generation of autonomous driving—from driverless transport systems in industry to automated transport of patients in retirement and nursing homes.

With the combination of PRT and MEMS, such complex, dynamic scenes can be captured in detail in real time. This creates a comprehensive database for completely new evaluations using artificial intelligence (AI) tools. As a compact and cost-effective sensor, the R3000 will make high-precision 3-D measurements available for a vast range of applications. In combination with advanced algorithms, the sensor will significantly drive development in the field of autonomous vehicles and service robotics - not only in manufacturing plants, hospitals or nursing homes, but in all areas of life.