www.industryemea.com

08

'15

Written on Modified on

With a 25-years’ experience in Industrial Automation, Delta Group is now directly present in Italy, too

Delta Group, based in Taiwan, is a world-class provider of industrial automation solutions and a global leader in power and thermal management technology. The company recently announced the opening of the new Italian subsidiary based in Milano and managed by Luca Cavagnari.

In recent years Delta has transformed from a product provider toward a solution provider and the businesses of the Group now encompass power electronics, energy management, and smart green life. Delta’s brand promise “Smarter. Greener. Together.”encourages the development and broad application of smart, energy-efficient solutions.

Delta is devoted to innovation and is systematically developing new products and technologies, and invests over 5% to 6% of annual sales revenue in R&D. The R&D facilities are located in Taiwan, China, Thailand, Japan, the U.S., and Europe.

Delta Group is organised in three main business lines: Power Electronics (Embedded Power Supplies, Mobile Power Supplies, Fans and Thermal Management and Electronic Components for ICT equipment), Energy Management (Industrial Automation, Telecom Power Systems, Mission Critical Infrastructure, Renewable Energy, Automotive Electronics & EV Charging) and Smart Green Life (Networking Systems, Display and Visualization, LED Lighting and Healthcare Devices).

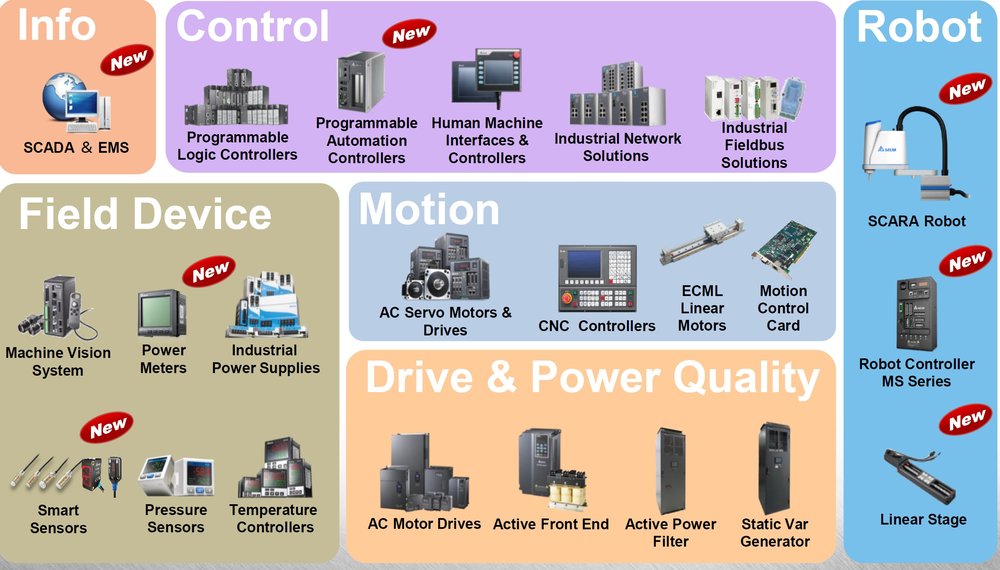

In particular, with a deep knowledge and experience in automation control, the Industrial Automation Business Unit (IABU) of Delta focuses on "Drive, Motion and Control" and has developed a wide range of products, like AC motor drives/ Inverters, AC Servo Motors and Drives, Temperature controllers, Programmable logic controllers (PLCs), Human machine interfaces (HMIs), Timers/Counters/Tachometers, Rotary optical encoders, High-Speed Motion Control Systems, Industrial Fieldbus Solutions, Text Panels, Industrial Power Supplies, Pressure Sensors, Industrial Ethernet, Machine Vision Systems, Active Front Ends and Active Power Filters.

The first IABU office was established in Europe already in 1990 and had a spectacular growth (+26% each year, with a turnover of around 700 M USD last year). In 2014 the total turnover pf Delta Group reached 8 billions of dollars and the Industrial Automation Business Unit contributed with a share of approximately 20%.

At present, IABU has built manufacturing facilities and professional R&D centers throughout Taiwan, China, and the US, along with sales offices and service centers deployed around the world. While striving for "quality, reliability and excellence", IABU will continue to progress in the field of industrial automation technology and enhance the quality and environment of our life with an endless pursuit of innovation.

IABU R&D teams continue researching and developing key technologies, producing innovative products in industrial automation; for example many OEM's use Delta automation products for processing machines used in the food industry, textile industry, chemical industry, electronics industry, metal industry and plastic industry. Delta automation equipment is also used in the pharmaceutical industry, printing industry, as well as for energy saving air-conditioning and water treatment facilities. In recent years, Delta has integrated industrial automation products, developed industrial control networks, and offered integration services to clients around the world. To-day Delta is a respected worldwide manufacturer, and also one of the leading brands in the industrial automation market in the Far East region.

A new subsidiary in Italy

As a multinational company, Delta is spread over the world with direct branch offices and local distributors in about 50 Countries.

In particular, Delta EMEA Headquarters are located in Hoofddorp, The Netherlands, while subsidiaries and distributors are present in the main Countries.

Recently a new subsidiary was established in Italy, a market that was previously covered by a distributor.

“Twenty years ago Delta decided to move into Industrial Automation,” says Luca Cavagnari, Business Development Manager Italy at Delta Europe. “We did it very well in Europe, Middle East and Africa, mainly through distributors. But we reached the point now where large customers were expecting us to have our own activity. So, we started to switch from a distibutor-based organisation to a situation where we have our own operations country by country. That helped us to offer a better local service, with people that have a direct contact with customers and applications and have a better knowledge of the market and of the next generation of products.”

Italy is very attractive for the kinds of products Delta can provide to the manufacturing market. “Italy is more interesting for us than the German market,” continues Luca Cavagnari. “Because there are not many local manufacturers of automation equipment, Italian customers are more open to other companies entering into the market compared to German customers. Also the fact that most of the Italian production is being exported was an attraction for Delta, because Delta is very well known in many final markets of Italian machines, particularly in Asia. This made Italy the number one choice for us. In addition, in Italy we found a good background of industrial automation and very good talents and application knowledge, because in Italy there is so much industrial automation activity. Though our headquarters are in the Netherlands, but our main sales operations for industrial automation will be in Italy.”

As the market opportunities in Industrial Automation for Delta are fastly growing, the company decided to support local distributors with a direct presence. “Up to last year, the Italian market was covered by a partner distributor - SIT Trasmissioni (now SIT Automation)”, says Luca Cavagnari. “But since June 2014 Delta established a direct presence on the Italian market to support the distributor. We are progressing very well and our full operations in Italy will start in September this year. The products we are going to push more in Italy are frequency inverters, servo drives and all forms of motion control products. But the experience of our distributor SIT will help us to promote also other products, like PLCs and process controls. In Italy, Delta wants to establish a direct presence to become a support for customers and distributors. Delta believes in automation technology and wants to show the market that can be a major player in the Italian market. Everyone that is able to do his job in the right way will find an opportunity, not a menace, in our decision.”

Italy is the second biggest market - after Germany - for Industrial Automation in Europe. For Delta, the main markets in Italy are packaging, food&beverage, machine tools, elevators and Intelligent Buildings.

Delta decided to start from Italy because Germany is an overcrowded market, with very strong local manufacturers. “It is not easy to be successful in an almost saturated market, with a huge offer from other competitors,” stresses Cavagnari. “The Italian market, on the other hand, is more open than the German market. Though the competition is high, in Italy, there are still some segments where Deltra can offer a good solution. Delta will not replace the Italian distributor, but is going to give them support for a more effective presence on the market. Through this project, Delta would like to give a strong message to the market: Delta believes in the Industrial Automation market segment and is willing to provide good, strong and performing solutions at a competitive price.”

Actually, Delta has a comprehensive portfolio that is continuously expanded and enhanced. “Looking at the individual products, Delta is very competitive, but the real added value of Delta is the ability to propose complete solutions, specially for small and medium machines - i.e. machines where the weight of the electronic part is very high compared to the weight of the total automation solution - with a good balance between product range and price,” says Cavagnari. “In summary, Delta offers a full range of products with good performances and a good price/performance ratio. Delta can supply small and medium machine manufactures a good solution based on good products, with good performances at a competitive price.”

Delta is often compared to some other European automation company that was able to grow at a very high rate in the recent years. Indeed, Delta’s growth rate is even higher, though the economy situation and the saturated market are not encouraging new investments. What is the secret of this outstanding success?

“It is true that the past history of Delta is similar to the history of other popular European brands of Industrial Automation that were established in Italy 10 or 15 years ago,” explains Cavagnari. “The growth that we would like to achieve and our outlook expectations are indeed much higher compared to these very well know names. There are no secrets. The main reason is in the comprehensive product portfolio that Delta is proposing. In addition, Delta is very strong in frequency inverters, with very performing products, a very complete range and an excellent price/performance ratio. This product range is the key that allows Delta to approach new customers. But Delta can also propose easy to implement complete automation solutions, with a good price compared to other competitors. By the way, our main competitors are not PC manufacturers or companies offering mainly PCB-based solutions, but companies that, like Delta, are based in the Far East.”

What’s around the corner in the Eurpoean rodmap of Delta?

“The goal of Delta in Europe is to establish a direct presence in single Countries for automation technology in some cases replacing local distributors, in other cases supporting them,” says Cavagnari. “Delta will invest a huge amount of money in this project with a very sharp growth expectation in the coming years because of two main reasons: on one hand, Delta will leverage on the market segments where the company is already very well known; on the other hand, Delta will expand the product portfolio, embedding in its products at least the same performances - or even more performances - compared to the products offered by its competitors. This investment will specially concern motion control systems, PLCs and HMIs. Delta wants to propose a complete automation technology solution with good performances, at the right price.”

There are few products in our Industrial Automation Business Group portfolio that are still not pushed on the European market: for instance, some devices for machine vision and for vision detection or CNC. The main reasons are quite clear: first, these kinds of products need a very strong technical support that at the moment Delta can’t afford for each single customer, but only for big customers. Second, this market at the moment is overcrowded and very closed. “Let’s take the CNC market as an example,” says Cavagnari. “The 80-90% of the market is dominated by very well known brands and is not very easy to propose our solutions.”

From Hannover Messe to SPS

Recently, Delta announced a range of smart industrial automation solutions, designed specifically to enhance the productivity and energy efficiency in a broad spectrum of sectors and applications in the Europe, Middle East and Africa (EMEA) region.

SPS-IPC-DRIVES Italia 2015 provides Delta with the opportunity to demonstrate its capabilities in expanding the degree of innovation, integration and adaptability of its industrial automation portfolio. These are:

- The newly-launched PAC Motion Control Solution that includes Delta’s PAC MH-1 Series controller which differentiates from peers by offering greater programming flexibility with ready-to-use specific APIs such as CNC and robot control for dramatic simplification of the implementation process. High-performance multi-axis control processes such as lineal, arc, helical and high-speed continuous interpolations are supported by the excellent synchronization and precise control offered by the built-in EtherCAT and Delta’s own DMCNET communication interfaces. Thus, this solution is ideal for complex industrial processes where PLC-based technology shows limited reach such as thermal cutting, glass cutting, woodworking and stone milling.

- The new SCARA Robot Solution that integrates the new SCARA DRS40L Series with the robot controller ASDA-MS Series. The former offers an arm length of 400mm, a load of 3kg and sensor-less compliance while the latter boasts built-in servo drive technology. This unique simplified architecture enables motion control of up to 10 axes (4-axis robot + 6 external axes) which translates into daily productivity improvement by up to 3 times in certain industrial processes. Smart identification and inspection functionalities can be added through further integration of Delta’s DMS machine vision system. Delta’s SCARA solution is suitable for industrial processes in the electronics, materials (rubber, plastics, metal), logistics sectors that require high-speed and high-precision such as assembly, coating, transporting and packaging.

- The Distributed Motion Control System that features Delta’s newly-launched human-machine interface HMC Series which boasts built-in PLC functionalities and is capable of supporting motion control of up to 12 axes by supporting our very own DMCNET high-speed motion control system. The intelligent 3-axis servo drive ASDA-M Series acts as a “smart slave” and enables synchronous interpolation for ultimate control accuracy. Therefore, this platform brings high standards in terms of precise positioning and speed for 3-axis and 5-axis Cartesian robots and also for coil winding machines and gantry control platforms.

- A Factory Energy Management Solution that integrates Delta’s own industrial visualization SCADA System DIAView, industrial Ethernet switches, mid-range PLCs AH-500 Series, vector control drives CP2000 Series and power/temperature meters into entire manufacturing facilities. This architecture enables comprehensive visualization of the manufacturing process, energy consumption, power quality and electricity cost analysis with intuitive and user-friendly interfaces. With its remote monitoring capabilities, this system supports decision-making processes for productivity and energy efficiency enhancements.

- Injection Molding Machinery Solution: The Hybrid Energy-saving System (HES) is a living proof of how Delta integrates solutions for enhanced productivity and energy savings. By leveraging Delta’s HES, molding machinery consume 40% less energy than variable displacement pump hydraulic systems. Automation devices such as HMIs, PLCs, temperature controllers and AC motor drives enable precise machinery speed control in order to reduce oil temperature by 5 to 10°C. This effect reduces 50% to 60% of oil usage and helps extend the lifetime of the hydraulic components.

- Solutions for the Food & Beverage Industry integrate Delta’s DMC machine vision control system for rapid detection or package defects and package content/direction confirmation for example. Delta’s mid-range PLC AH-500 Series offers high-extension system architecture to large-scale beverage production lines (maximum 100m by cable or 2Km by optical fiber).

- Energy Regeneration Solutions that include one energy-saving solution for cranes and one for elevators. The former offers up to 30% energy savings in industrial crane operations by integrating the heavy-duty control drive CH2000 Series with the power regenerative unit REG2000 Series. The latter reduces >50% energy consumption in either cargo or passenger elevators by integrating the REG2000 with Delta’s Integrated Elevator Drive IED Series.

Welcome to visit Delta’s stand at Hall 3 - Booth A068 between May 12th and 14th, 2015, SPS-IPC-DRIVES Italia 2015, Parma, Italy.