www.industryemea.com

22

'21

Written on Modified on

Modular preparation system with dual-substance nozzle nebulises hydrogen peroxide

Safe chemical disinfection saves time and costs. A scalable system with a compressed air-operated dual-substance nozzle and flowmeters from Bürkert allows cost-saving and reliable disinfection with hydrogen peroxide.

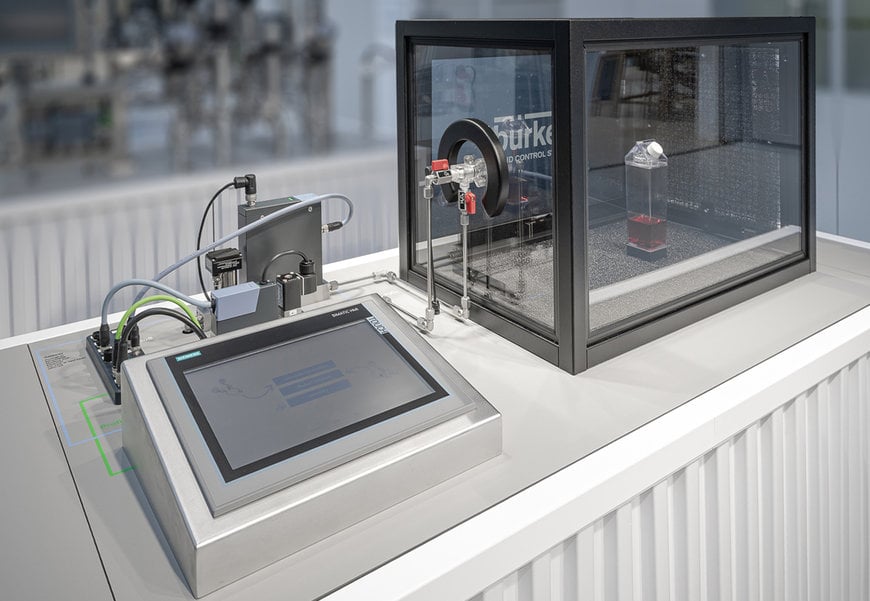

Bacteria, viruses and fungal spores are everywhere and must be reliably killed for sensitive processes in the pharmaceutical and food industries or biotechnology. A residue-free disinfectant such as hydrogen peroxide (H₂O₂) is ideal for this purpose. To ensure that this works reliably in practice, Bürkert Fluid Control Systems has developed a scalable system for chemical disinfection with a compressed air-operated dual-substance nozzle that ensures homogeneous and fine aerosol formation with minimal chemical and energy input and thus meets the highest disinfection standards (image 1).

Hydrogen peroxide vapour has a particularly strong corrosive and cytotoxic effect and, due to its strong toxicity to many micro-organisms, is an effective disinfectant. The wide, independent control range for air and liquid volume allows many different settings for throughput and atomisation rates. This makes the system individually adjustable, very flexible and suitable for a wide range of applications such as the sterilisation of packaging, HEPA filters or for room disinfection.

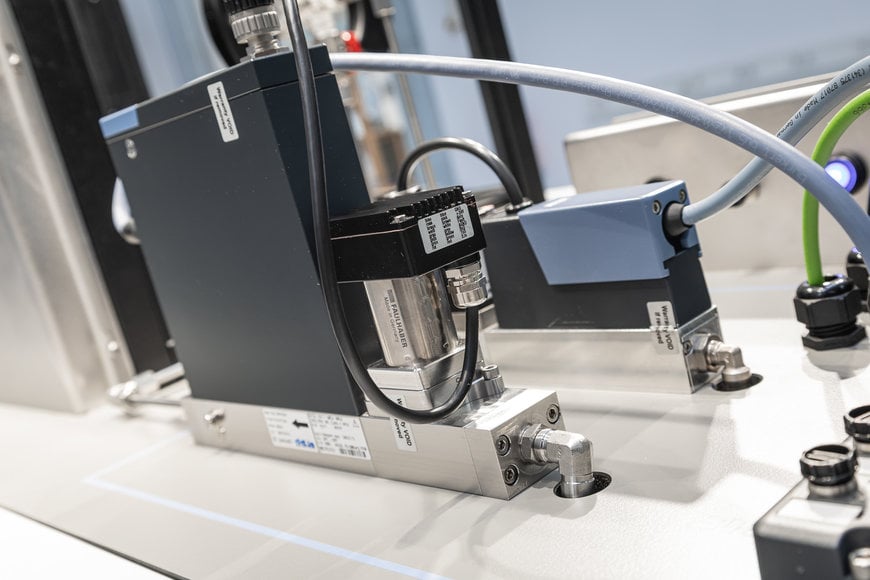

Reliable result with minimal use of disinfectants

30 to 35% hydrogen peroxide is pumped by overpressure from a stainless steel storage container to a liquid flow controller (LFC), which precisely regulates the amount of liquid. In parallel, the atomising air is precisely metered to the nozzle via a mass flow controller (MFC) (image 2). This takes over the atomisation of the liquid phase from fine droplets to the finest mist, which then evaporates easily. Due to the exact measurement of the material flows, the disinfection time can be precisely determined, which saves time and disinfectant with exactly reproducible disinfection results. All parameters such as time duration and amount of substance can be exported and stored digitally for quality assurance. The disinfection system is modular and available in different versions. Depending on the customer's requirements, variants with an additional heater or integrated flushing are available in addition to the basic version with nozzle, reservoir and controllers and dosing valves with matching pipelines. If required, the scalable complete modules also include integrated safety devices or complete control cabinet integration with PLC control.