www.industryemea.com

20

'21

Written on Modified on

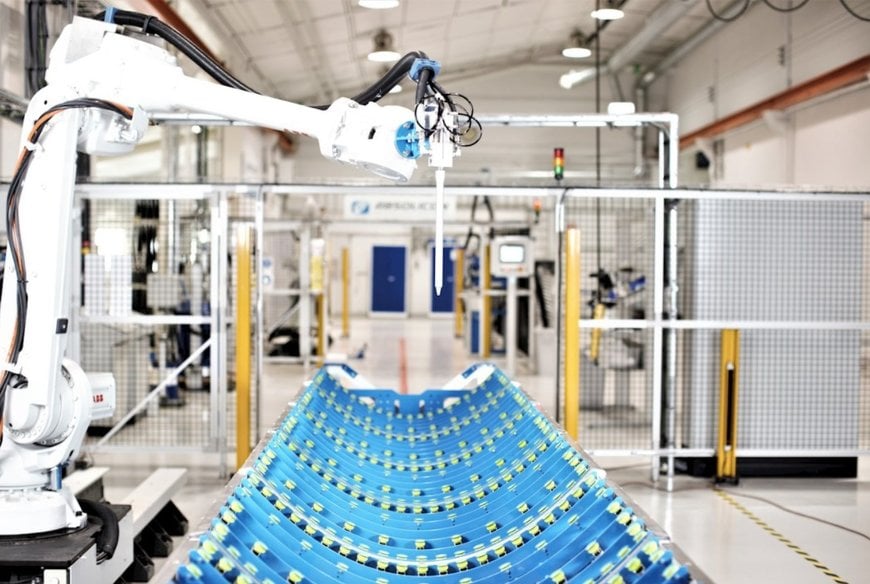

ABB robots improve automation in the solar industry

“The development of this automated production process allows us to launch a vast opportunity study by radically reducing the price of our solar collectors while guaranteeing constant manufacturing quality of a very high level.

The productivity provided by ABB robots allows us for the first time to make solar energy competitive in terms of price compared to traditional industrial heating solutions, explains Joakim Byström, CEO of Absolicon. Our new automated production line can produce a complete solar collector every six minutes. So unlike our competitors who rely on a mostly manual manufacturing process, we get to get the job done with just five operators, two robots and a small number of components. "

Absolicon has been developing sustainable solar technologies for 20 years and producing parabolic solar collectors that are the most efficient in their class, generating heat and steam up to a temperature of 160 degrees to meet the needs of industrial companies and consumers. district heating networks.

"We are pleased to see that ABB's robotic solutions are helping to improve the productivity, quality and profitability of Absolicon's production line, enabling it to bring a renewable energy product to market at a competitive price," explains Sami Atiya, President of ABB's Business Area Robotics & Discrete Automation. By enabling Absolicon to ramp up production, from three units per day to one every six minutes, our robotic solutions play a key role in accelerating the widespread adoption of sustainable technologies, while enabling Absolicon's production partners to continuously manufacture solar collectors globally. "

“Our ambition is to enable the cost-effective mass production of solar collectors worldwide, and thus to produce heat directly from sunlight,” Byström adds. Our partnership with ABB to create this automated production process is one of the key elements that will enable us to achieve our goal, while ABB's international service organization will prove to be a most valuable resource for us. our new customers as we roll out our new automated production line globally. "

The next phase of this project foresees the supply of complete robotic production lines to manufacturing partners globally, knowing that ABB and Absolicon have agreed to collaborate in the development, sale and marketing of these robotic production lines. at the International scale.

The first installation has already been delivered to a partner in China, and framework agreements for the acquisition of robotic production lines have been concluded with various companies in a dozen countries, with ABB responsible for supplying the robots for all these new facilities.

www.abb.com