www.industryemea.com

09

'21

Written on Modified on

4 Reasons Why Mobile Robots Are The Solution To Operational Safety

One of the main concerns in high-risk industries like warehousing and manufacturing is workplace safety, and let’s be real: the pandemic is not exactly making it any easier.

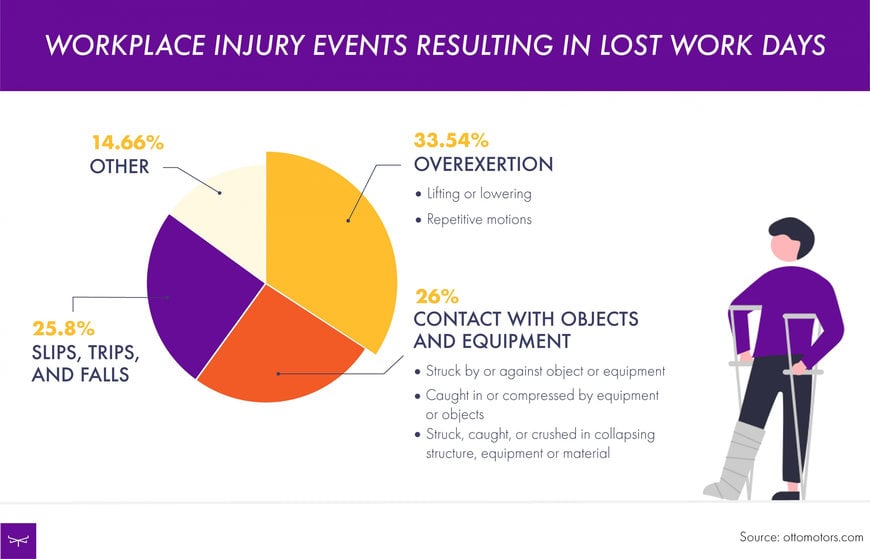

According to research done by Meili Robots, there were 5,333 fatal occupational injuries recorded in the U.S. — that’s an increase of 3.6% since 2017 and the highest annual number since 2007. Workplace safety is closely linked to a company’s productivity, too. In fact, considering productivity losses and the like, workplace injuries cost the U.S. more than $1M per week.

Many safety concerns that arise when traditional robots like manually operated forklifts are used can be addressed by adopting mobile robots. 4 ways in which autonomous mobile robots (AMRs) can improve operational safety can be distinguished:

1. Prevention of Collisions Through Improved Visibility

Thanks to built-in sensors, mapping, routing, LiDAR scanners, and universal fleet management, AMRs are able to autonomously navigate around people and obstacles on their route while simultaneously mapping out the best route.

Not only will this allow companies to remove human workers from highly dynamic, dangerous environments, but it also promotes higher efficiency levels by minimising human error and collisions.

2. Limitation of Contact With Dangerous Machinery

The safety of forklifts is a common challenge in the warehousing industry, with the Occupational Safety and Health Act (OSHA) estimating 85 fatal accidents, 34,900 serious injuries, and 61,800 non-serious injuries on an annual basis. In fact, more than 11% of all forklifts are involved in an accident, and with an average lifespan of eight years, this means that each forklift has a 90% chance of causing a serious accident.

By adopting mobile robots — either as an alternative or addition — to the work floor, the risk of death and injury will be substantially decreased while at the same time keeping the business up and running without harming productivity levels.

3. Automation of Repetitive Tasks

More than 33% of worker injuries in manual material handling is caused by the repetitive nature of the work. By taking on these repetitive, high-risk tasks, mobile robots will be able to reduce the risks of collisions while simultaneously optimising operational efficiency.

4. Easy Adoption of Social Distancing Measures

Since the COVID-19 pandemic, safety concerns have been heightened across many industries. As manufacturing work usually requires close contact between workers, it has been a challenge to keep the operations moving while adapting to mandatory guidelines.

It is therefore also no surprise that the pandemic has increased the adoption of mobile robots while bringing more awareness to the ways in which mobile robots can not only improve operational efficiency but also make it easier for companies to adapt to social distancing measures.

www.meilirobots.com