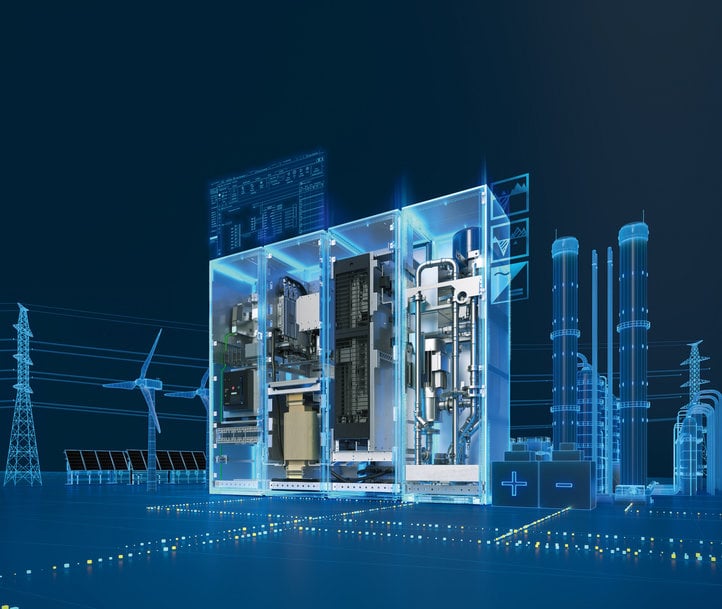

New Sinamics PCS Power Conversion System for battery storage systems

With Sinamics PCS, Siemens presents a new power conversion system for battery storage applications.

Siemens presents Sinamics PCS, a liquid-cooled, robust power conversion system for battery storage systems.

- Siemens presents liquid-cooled, robust power conversion system based on proven Sinamics S120 platform

- Grid converter comes with certification in accordance to VDE-AR-N 4110 and with validated simulation model for easy project planning, optimization and integration into the power grid

The Sinamics PCS grid converter makes locally generated battery power usable for industrial and public power grids. Sinamics PCS controls the charging and discharging process of the battery and helps to handle load peaks and grid disturbances via the battery storage, to store the electricity in an energy- and cost-efficient manner and to bring the energy stored in batteries efficiently and reliably into the grid.

The grid converter is based on the industry proven technology of the Sinamics S120 platform and works particularly energy-efficiently thanks to its liquid cooling. The compact and robust power conversion system includes connection technology and control, line filter, converter and liquid cooling and can be easily integrated as a complete system in control rooms or containers.

Sinamics PCS is certified in accordance with the "Technical Connection Rules” VDE-AR-N 4110, which is valid in Germany. This means that stationary battery storage units can be connected to the public medium-voltage grid with minimal system certification effort.

A validated Matlab/Simulink simulation model simplifies and accelerates the planning, optimization and grid integration of the power conversion system. And thanks to the Sinamics Startdrive tool in the engineering framework TIA Portal the grid converter can be integrated into the drive world comfortably. Operating states and system parameters can be read out via the Profinet communication interface. This allows the data from operation to be monitored and analyzed and makes precise statements about upcoming service work possible.

www.siemens.com