www.industryemea.com

17

'13

Written on Modified on

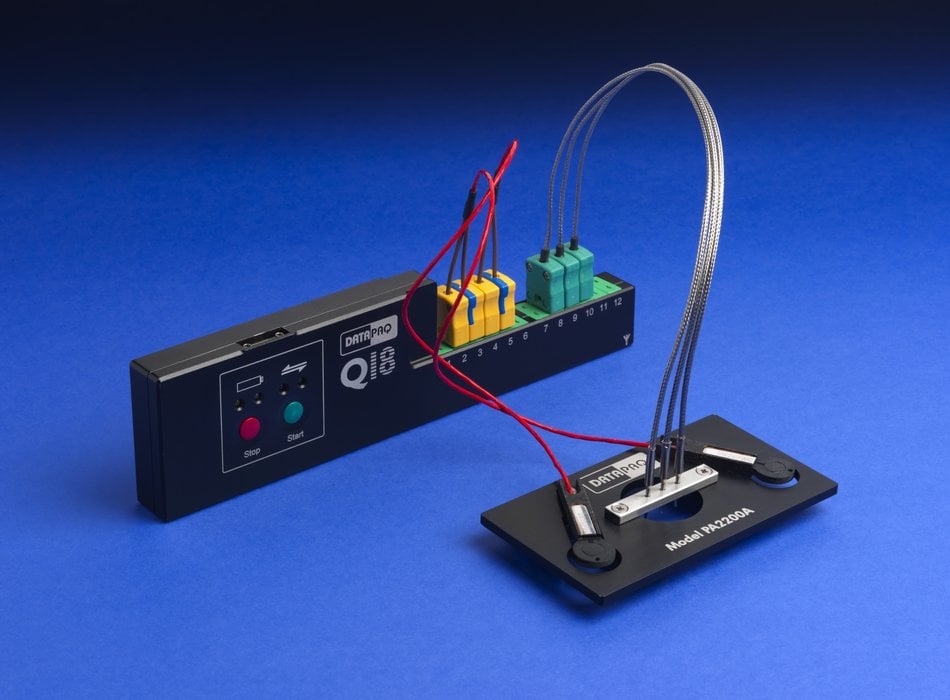

Datapaq solution for repeatable results in selective soldering

Cambridge, UK – Working with a tier 1 electronics supplier to the automotive industry, Datapaq has tailored a temperature monitoring solution for documenting the repeatability of selective soldering processes. This development has become necessary as automotive manufacturers are increasingly requiring their suppliers to perform statistical process control. The economic argument for immediate quality control is strong, too: since margins are small in this industry segment, and the costs of product failures are high, measuring and controlling each process ensures profitability. Datapaq’s low-cost solution monitors both the pre-heat stage and the dip soldering stage and generates detailed temperature profiles that enable users to compare the performance of different machines, adjust parameters if necessary, and reduce setup time for new batches. Crucially, the system is small and light enough to pass through the process along with the printed circuit boards. It consists of a Q18 data logger and a PA2200A fixture holding two thermocouples for the pre-heat stage and three thermocouples for the dip soldering stage. The dip soldering probes enable the monitoring of solder temperature as well as dwell time in the solder (contact time). They can be adjusted to allow for measurement of contact time at different heights. The customer uses Datapaq products to monitor all soldering processes. In addition to minimizing training costs, this facilitates the establishment of best practices since central process development engineers can compare measurements from all their assembly facilities.