www.industryemea.com

20

'12

Written on Modified on

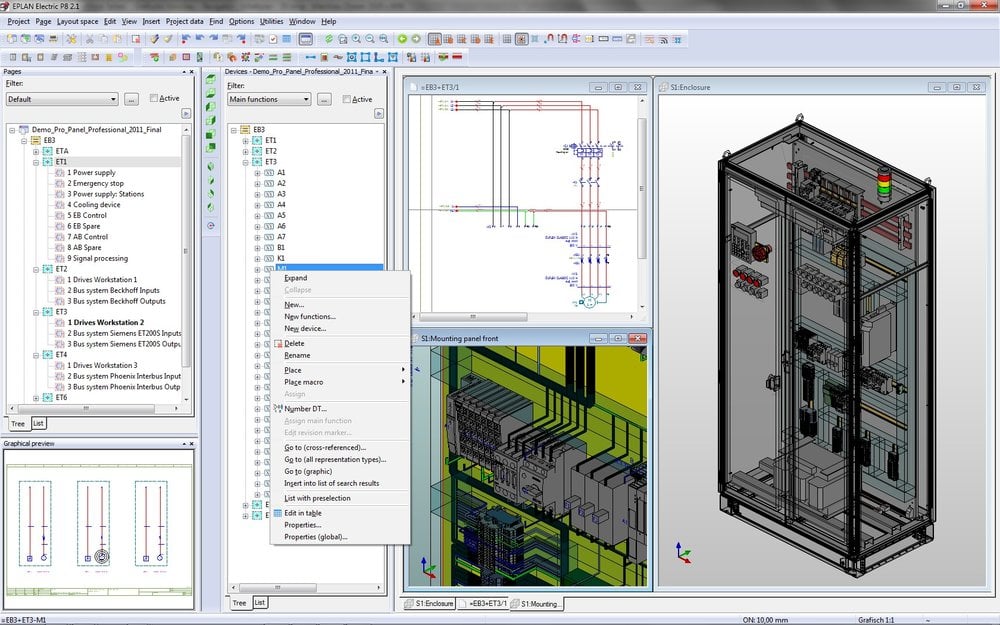

EPLAN Platform 2.1 - Engineering processes actively accelerated

The EPLAN Platform 2.1 centers around standardization and automation. Automatic macro updates, targeted use of test routines - these and further functions bring about rapid results and increased quality. Even larger projects can be managed easier with the "EPLAN Multiuser Management" module.

Multiuser Management

Large automation projects often will be worked on by very diverse project participants. How can one keep that amount of data transparent and compact? The new module “EPLAN Multiuser Management” provides the solution. It is able to divide projects into process areas, which can then be structured using identifier blocks. By the way, the structure is done based on the identifiers already existing in the project. Setting up process areas can optionally be designated to the user, or it can be centralized with the administrator. This method simplifies concentrating on the respective areas of responsibility. At the same time EPLAN Platform 2.1 ensures that all project information is globally synchronized. Helpful navigation functionalities are available as well. A clearer overview is created, system reaction time for the user speeds up, and it consequently leads to increased quality in project design.

Creating variants with "Rotating and Mirroring"

A new functionality has been developed especially for fluid power engineering; it gives a distinctive performance surge to project design, as well as master data creation. "Rotating and mirroring" contains its own logic and speeds up i.e. creation of schematics or fluid plans up to factor 2. Only one half of the plan is left to be designed by the user - the second half can be generated with the intelligent mirroring technique. In the case of symbols, the acceleration can be as high as factor 8, because the eight angle variants no longer need to be done manually. Creating one single variant suffices, and all other representations are delivered by the system with the respective automatic rotations and mirroring.

Automatic correction checks

Manual project checks can take up considerable time – it is therefore a real plus if the system can take over this work. The check type "Prevent errors" was already introduced with version 2.0; it actively prevents the user from entering incorrect data. The new version continues to pursue this path. The user can now apply check routines specifically to newly entered corrections during a project edit. The EPLAN check routines are concentrated specifically on the newly edited project sections, which leads to an even higher quality standard in machine and plant documentation. This clear focus facilitates specific testing of corrections and creates a sustained increase in project quality.

EPLAN Service Pack 2.1

The EPLAN Service Pack 2.1 release includes new program functions in the areas of terminal design, including reports, part navigators, message management, automated processing, text editing / display and much more. The Service Pack 2.1 can be installed without having a previous installation of version 2.1, so existing customers can benefit from the updated features immediately with one simple installation.

Terminal Reports

Some benefits of the new service pack are evident in terminal diagrams, as you can now output all the connection points from a terminal side by side in a row format. For this extended functionality in the report, the placeholders for the terminal diagram forms have been enhanced. Thanks to the new report functions, the design of terminal diagrams can now be more individual. Information can be displayed more clearly, and in an easy-to-read and space-saving manner. This way, all downstream project steps, such as manufacturing and mounting, can be supplied with all key project wiring and cabling information in an optimal and compact manner. But in the area of maintenance and repairs, too, application engineers can now access the necessary connection information thanks to extended reports.

Message Management

The check run messages highlighted in message management can now be synchronized with the opened navigators. For this, the synchronize selection menu item can be used in the popup menu of message management. The synchronization of the display in the message management and navigators, allows the user to find the objects in the navigators that cause the errors and easily jump to objects associated with the error message. They can also access the objects properties via the navigators to speed up the processing of check run messages.

Automated project processing

The automated processing of projects is now managed by the use of EPLAN schemes. For this purpose, all actions that are to be run in an automated manner at once are stored in a user-specific scheme under a specific name. As is customary in EPLAN, such a scheme can be copied, edited or deleted. Schemes can also be imported or exported. There is no editing of scripts for automated processing. The uniform design of settings as a scheme facilitates your operation of the program. Scripts are now stored centrally through the use of schemes and therefore there is no duplication of the same scripts in multiple projects. Using automated processing it can be easily defined – and with the new schemes, now available for every user in the company – a uniform basis for the standardized processing of projects is employed. Scripts already defined can be applied easily by importing them and storing them as schemes – facilitating the foundation for full and comprehensive standardization.

Images

EPLAN_Platform 2.1_engl: EPLAN Platform 2.1 is synonymous with interdisciplinary engineering, driving standardization and automation.

EPLAN_Service Pack 2.1_engl: EPLAN Service Pack 2.1 includes new program functions in the areas of terminal design, part navigators, message management, automated processing and text editing.