www.industryemea.com

30

'11

Written on Modified on

Eplan Operational Sequence module: documenting operational sequences better

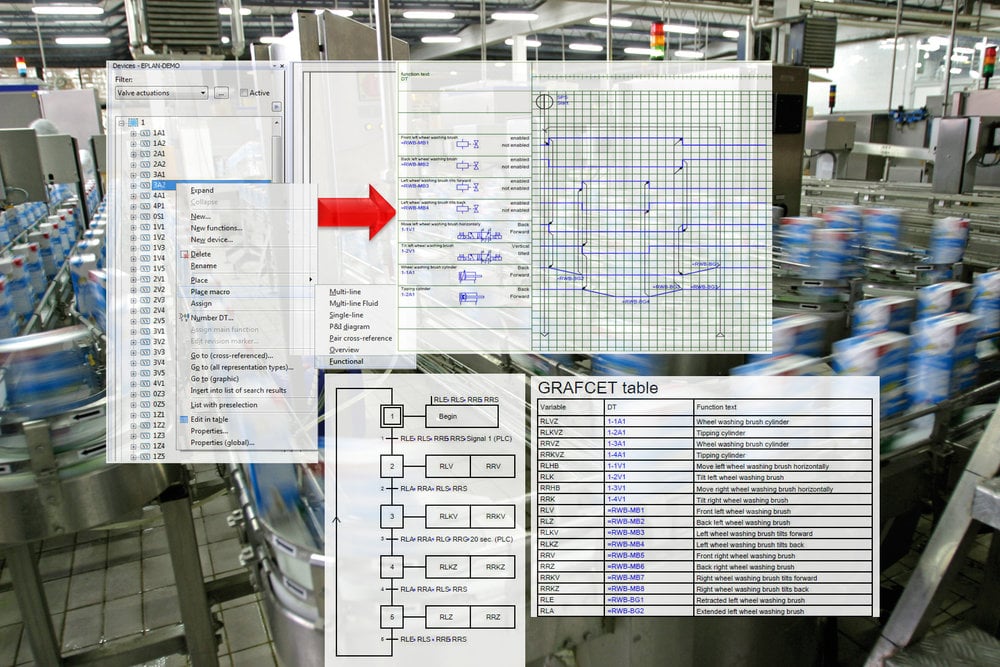

Knowing the sequence of operations is always helpful, especially in machine and plant design and the programming of their control systems. ‘Eplan Operational Sequence’ now documents the functional timeline of a machine/plant by using convenient process descriptions. You have the choice between a functional diagram or a GRAFCET standard. PLC programmers will benefit from the seamless documentation, controlling the interactions of actuators and sensors.

It has become increasingly difficult to represent a functional timeline for machines and plant systems clearly, because of an ever increasing complexity and the mechatronic interaction of sub-elements, even though it is an indispensable component for planning a steering and control system. Eplan introduces the solution with 'Eplan Operational Sequence´. The new Eplan Platform module option conveniently includes process descriptions into the overall control systems documentation. The software offers various flexible ways of describing these operational processes: frequently used function diagrams as well as the newest version of GRAFCET diagrams (Graphe Fonctionnel de Commande Etapes/Transitions) are supported as well. The benefits are clear: The PLC programmer receives timely information about the necessary actuators and sensors and their desired operational interaction and timeline. It provides valuable preplanning time for machine controls and accelerates the engineering processes. Changes to electrical and fluid engineering plans can then be integrated into the process descriptions automatically and documented perfectly afterwards.

Insert values - and done

The Device navigator will from now on be the central dialog for inserting Eplan functions into a function or GRAFCET diagram. It doesn't matter if the function has already been placed into the schematic, or if it will be created as a new device. Only the values for time/step scales, as well as the process sequence, must be entered into the diagram after placement. The necessary forms are included and values may even be inserted as macros quite easily. The only remaining manual step will be the process sequence with the aid of graphic elements such as polylines. An automatic translation into foreign languages is available right from the start, as well as other quality increasing functionalities in the process sequences.

Flexibility for any application

The ´Eplan Operational Sequence´ module option will be available with the release of Eplan Electric P8 2.1 in the fall of 2011. Is it part of Eplan Fluid, the second Platform system, included with the delivery scope of version 2.1. It doesn't matter if the fluid software has been installed as an individual program, or as an add-on to the CAE System P8.

Background:

Operational sequence sheets are an important component of the engineering process and are indispensible for the following, planning of machine and plant controls. Furthermore, they are often required in customer documentations (automotive suppliers for example), to optimize the cycle time of the system as a whole. In regards to GRAFCET Standards, GRAFCET diagrams are representations of sequence controls for which a specification language according to DIN EN 60848 has been developed. In this case, the representation is about the function of a machine from the view of the PLC programmer, whereas functional diagrams offer only a simple mechanical view.

Operational Sequence.jpg: With the introduction of ´Eplan Operational Sequence´ the operational sequence sheets may be shown clearly as function diagrams, or also as GRAFCET diagrams (according to DIN EN 60848).

Insert values - and done

The Device navigator will from now on be the central dialog for inserting Eplan functions into a function or GRAFCET diagram. It doesn't matter if the function has already been placed into the schematic, or if it will be created as a new device. Only the values for time/step scales, as well as the process sequence, must be entered into the diagram after placement. The necessary forms are included and values may even be inserted as macros quite easily. The only remaining manual step will be the process sequence with the aid of graphic elements such as polylines. An automatic translation into foreign languages is available right from the start, as well as other quality increasing functionalities in the process sequences.

Flexibility for any application

The ´Eplan Operational Sequence´ module option will be available with the release of Eplan Electric P8 2.1 in the fall of 2011. Is it part of Eplan Fluid, the second Platform system, included with the delivery scope of version 2.1. It doesn't matter if the fluid software has been installed as an individual program, or as an add-on to the CAE System P8.

Background:

Operational sequence sheets are an important component of the engineering process and are indispensible for the following, planning of machine and plant controls. Furthermore, they are often required in customer documentations (automotive suppliers for example), to optimize the cycle time of the system as a whole. In regards to GRAFCET Standards, GRAFCET diagrams are representations of sequence controls for which a specification language according to DIN EN 60848 has been developed. In this case, the representation is about the function of a machine from the view of the PLC programmer, whereas functional diagrams offer only a simple mechanical view.

Operational Sequence.jpg: With the introduction of ´Eplan Operational Sequence´ the operational sequence sheets may be shown clearly as function diagrams, or also as GRAFCET diagrams (according to DIN EN 60848).