www.industryemea.com

12

'19

Written on Modified on

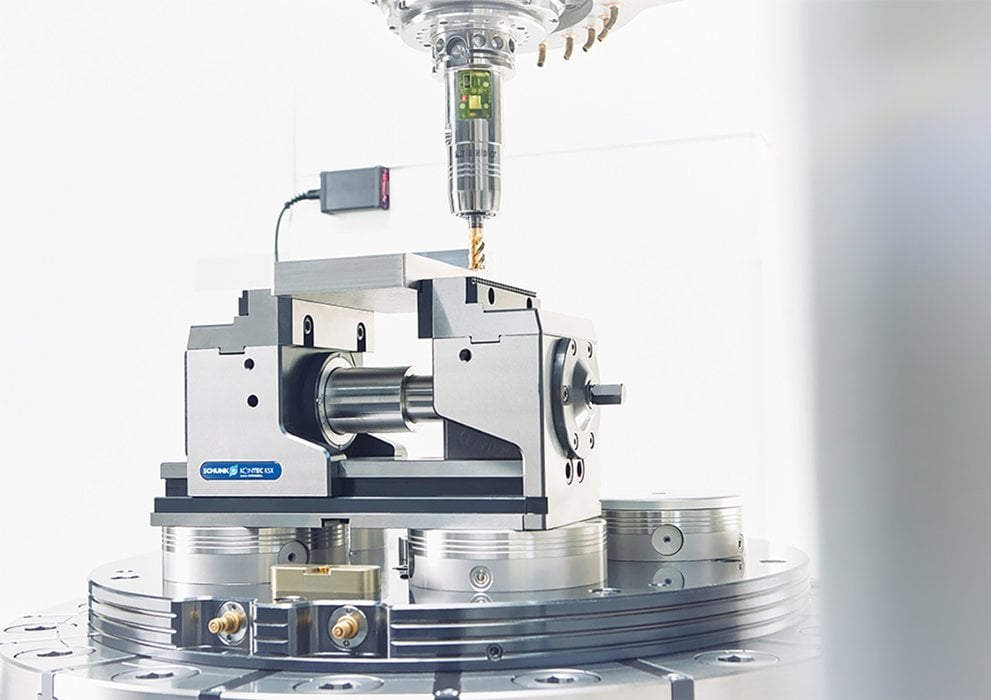

Smart clamping devices and gripping systems for the metal cutting industry

EMO 2019: "Smart loading, smart processing, smart networking – these three key topics will characterize industrial production over the coming five years," asserts Henrik A.

"Our clamping devices and gripping systems will enable detailed monitoring of the production process in real time and autonomously carry out corresponding reactions," says the Managing Partner. The best example of this: The sensory precision toolholder iTENDO, which will be available for pilot applications from fall.

It allows complete status monitoring and documentation of process stability, unmanned limit value monitoring, tool breakage detection, as well as real-time control of the speed of rotation and feed rate.

If the cut becomes unstable, the integrated intelligence intervenes immediately in real time and with no action required from the operator: depending on the situation, the process is stopped, reduced to previously defined basic parameters, or adapted until the cut returns to a stable range.

Digital twins of the toolholder series TENDO, TRIBOS and SINO based on DIN 4000 will also ensure consistency of data throughout the entire CAD/CAM process chain. They provide the perfect preconditions for simulations, collision observations and for shopfloor management.

Focus on automated machine loading

In the field of VERO-S quick-change pallet technology, SCHUNK is introducing a sensoric quick-change pallet module for the first time, which enables permanent monitoring of the pull down force and the clamping slide position, as well as of workpiece or pallet presence.

In addition, new VERO-S special components will be presented for aviation, 3D printing and workpiece direct clamping. Besides the following highlights, SCHUNK will showcase sophisticated concepts with an emphasis on automated machine loading.

Lean automated solutions, simple to implement up to cost-attractive ones, applications with lightweight robots to convenient palletizing solutions for flexible small-batch production up to ergonomic, collaborative solutions with the long-stroke gripper Co-act EGL-C in direct interaction with humans for form-fit handling of workpieces weighing up to 8 kg. SCHUNK at EMO 2019: Hall 3, Booth D30

www.schunk.com