www.industryemea.com

07

'19

Written on Modified on

Flight test passed

Inspection of sausages with machine vision.

One of the most important tasks of food manufacturers is the avoidance of contaminants in their products in order to minimise the risk of damage to health, expensive recall campaigns and the associated damage to image. The visual appearance of the food and its packaging also has to be appealing to the consumer in order to achieve the desired sales success in the supermarket.

In view of the high production speeds in the manufacture of food and beverages, it is largely impossible to carry out 100% effective manual quality control in modern plants. In many cases, machine vision represents an economical option for the inspection of foodstuffs and their packaging.

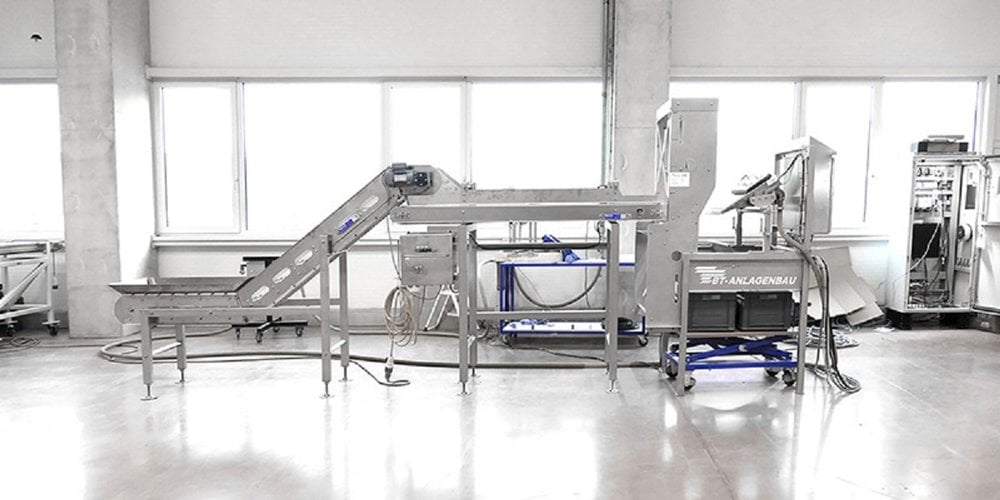

Wolf GmbH, represented by managing director Bernhard Oeller, has been using machine vision technology since mid-2018 for the quality control of sausages. The company, which is headquartered in Schwandorf, Bavaria, is one of the largest producers of sausage products in Germany and uses a spectacular machine vision system from BT-Anlagenbau in a plant that manufactures Berner sausages for the retail sector.

These products (which by the way do not originate from Switzerland, but rather from Austria and are named after their inventor, the chef Erich Berner Senior) consist of Wiener or Frankfurter sausages containing a portion of cheese and wrapped in smoky bacon.

"In order to manufacture the basic sausage, a synthetic intestine is filled with sausage meat and then smoked and cooked", explains Matthias Seeger, who was responsible for the development of the innovative inspection and sorting system at Wolf. "In the next step this synthetic intestine is removed by a peeling machine before the wrapping with smoky bacon takes place. The intestine can be regarded as a sort of baking tin that has to be removed before further processing of the sausages."

The intestine, which is made of cellulose, is generally edible and health risks can thus be ruled out. "However, consumers often think that intestine residues on the products are plastic or dirt, and consequently we need to make sure that sausages with intestine residue adherents are reliably removed from the process."

Lying or flying?

Seeger knew from other applications in his company that the detection of intestine residues ought to be possible using a suitable machine vision system. Following an initial unsuccessful attempt with another supplier, he enquired of STEMMER IMAGING in late 2017 about an appropriate detection system.

"Although STEMMER IMAGING do not carry out the development, implementation and integration of such systems themselves they were able to recommend the Austrian company BT-Anlagenbau, which already has many years of experience in machine vision and in the development of sorting and quality control systems of the most diverse types and with whom they had collaborated successfully in the past," Seeger recalls.

Following a joint inspection of the production plant and a detailed discussion of the specifications and goals, STEMMER IMAGING carried out intensive feasibility studies in order to compile the ideal selection of the necessary machine vision components. This determined that the obvious solution did not deliver adequate results: "We initially considered scanning the sausages with a line scan camera as they passed by on a conveyor belt", says Seeger.

"It quickly transpired that in this way a large part of the underside of the sausages could not be captured by the camera and thus couldn't be checked. Intestine residues on the side facing away from the camera would therefore not have been reliably detectable."

A solution for this situation was provided by the machine vision specialist BT-Anlagenbau with its 360° camera technology, which has already proven itself in a great many sorting systems: "Our idea was to inspect the sausages in flight with two line scan cameras situated opposite each other", explains Christian Hartbauer, who is responsible for the distribution and development of quality control systems at BT-Anlagenbau.

"In this way virtually the entire surface of the sausages can be examined for the widest variety of defects."

Up to 30 sausages per second

On the basis of this setup principle STEMMER IMAGING carried out further tests together with BT-Anlagenbau and drew up a recommendation for suitable machine vision components, which in the end were actually used in the system.

"In the system the required quality and speed of the image capture is ensured by two greyscale Linea line scan cameras from Teledyne DALSA with appropriate accessories such as heat sinks, suitable red LED lighting from Metaphase and lenses from Kowa equipped with polarising and bandpass filters", explains Jan Sandvoss, who is responsible for this application at STEMMER IMAGING.

"In order to conform to the strict standards in the food industry and to ensure the required sturdiness for daily cleaning, the cameras are housed in protective housings from the Allison Park Group (APG) with IP65 protection class or higher."*

The system has now been in operation since mid-2018 and has proven itself to be ideal. Matthias Seeger is delighted and describes the process sequence as follows:

"The peeled sausages are aligned via a conveyor belt and flexible cascades so that they lie longitudinal to the direction of transport of the conveyor belt and cannot roll around. The goods are then accelerated to about 2 m/s on this belt and, at the end of the belt, fly past the cameras integrated above and below, which then inspect the sausages in free flight."

In view of the high process speed little time remains for the detection of intestine residues, of which some are no larger than 1 mm², and the subsequent activation of the compressed air valves installed for the ejection. Christian Hartbauer calculates:

"Currently two different sizes of sausage with lengths of 90 and 160 mm are inspected by the system. The image capture alone takes 45 or 80 milliseconds respectively per sausage. After that only 70 or, in the case of the larger sausages, 35 milliseconds remain for the detection of intestine residues and the pinpoint blowing of the contaminated sausages out of the production stream. The rest are gently caught and fed to the further production process."

Adequate computing power for this task is provided by a high-performance Industrial PC with a real-time operating system, which can be operated by a touch screen. If necessary, individual images or statistical overviews can be displayed and adjustments to system settings made.

The system reliably detects undesired intestine residues from a size of 1 mm². After sorting, the good products have a purity of 99.999% depending on the defect size, which means that STEMMER IMAGINMG and BT-Anlagenbau have far exceeded our specifications. We can thus put our trust in a compact, inexpensive and highly precise solution that fully meets all our requirements.

Clever details

The high process speed and the strict requirements in the food production weren’t the only obstacles that the three partners had to overcome before the system was ready. For example, an air curtain was required in front of the camera housings in order to ensure that the accompanying traces of the product would not make sharp camera images impossible over the course of time.

For the blowing ejection, BT-Anlagenbau developed a construction with 80 very fast special valves with which the entire belt width of 400 mm can be covered. The nozzles are installed in a suspended position so that any condensed water runs off and cannot cause contamination.

"On account of the food regulations we had to ensure that only sterilised compressed air is used in order to rule this out as a cause of contamination", says Christian Hartbauer. The development was also made more difficult on account of the limited installation space: "We had to fit our system into an existing production space and design the system accordingly."

However, the companies involved overcame all of these challenges with flying colours and Matthias Seeger is very satisfied with the system, which is now running reliably:

"The system reliably detects undesired intestine residues from a size of 1 mm². After sorting, the good products have a purity of 99.999% depending on the defect size, which means that STEMMER IMAGINMG and BT-Anlagenbau have far exceeded our specifications. We can thus put our trust in a compact, inexpensive and highly precise solution that fully meets all our requirements."

Under the name Meat Sorter, BT-Anlagenbau now also offers the system it created to other customers who wish to solve similar tasks. Related systems from the company also sort other meat products such as rissoles, steaks or pet food according to criteria such as shape, size, weight and colour and detect foreign bodies, synthetic intestine residues or, using an optional hyperspectral extension, bone resides or the fat and water content of the goods as well as their freshness.

"On account of our many years of positive experience in cooperation with STEMMER IMAGING we trusted their machine vision components for this system too", Christian Hartbauer stresses.

www.stemmer-imaging.com