MX system for new applications and possibilities

New Walter CaptoTM toolholders and insert widths expand the range.

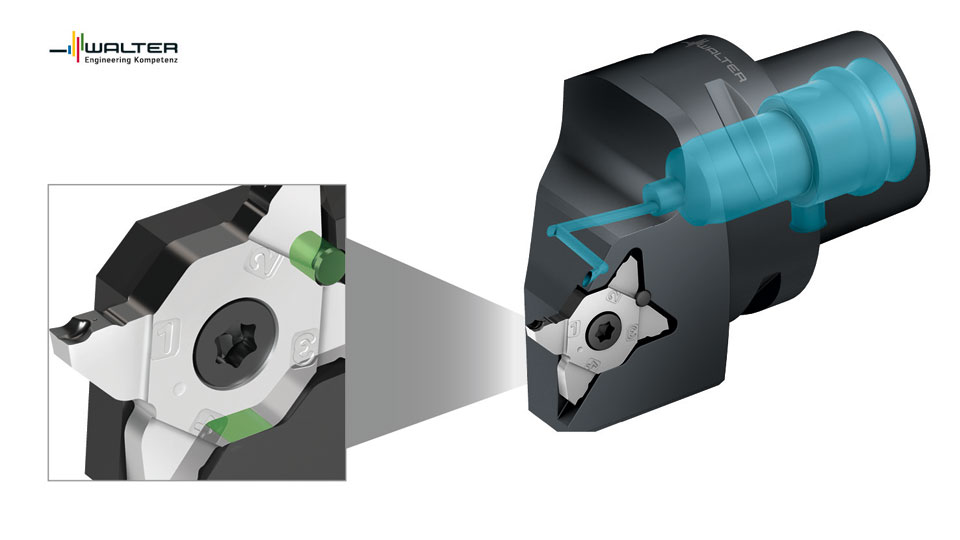

With Walter Cut MX, Walter AG brought a grooving system to the market which used proven methods while overcoming the disadvantages of existing competitor systems: With dowel pin location to counter handling errors for a high degree of change and positioning accuracy. With four-edged indexable inserts that can be used even after a cutting edge breaks for maximum cost efficiency.

And with a long tool life thanks to the Walter-specific precision cooling and the Tiger·tec® Silver cutting tool materials. A combination of stability, productivity and accuracy unlike anything currently available on the market. Now, Walter is expanding the MX range with Walter CaptoTM toolholders and larger insert widths.

With the new Walter CaptoTM monoblock tools (C3–C6), the MX system can now also be used on machines with Capto interfaces. In addition, there are new parting blades such as those used on automatic lathes and multi-spindle machines. Walter has completed the range with new grooving inserts and toolholders for larger insert widths, for example for pre-grooving large grooves:

Where previously only 0.80 mm to a maximum of 3.25 mm were possible, the insert width now ranges up to 5.65 mm – including the very common dimensions of 4 mm and 5 mm (maximum cutting depth 6 mm). The extensions are intended to make new applications possible for users of the MX grooving system: From mass producers, for example in small-parts production where a high degree of precision is paramount, to job shops, where the focus is on fast, precise tool changes and cost efficiency.

Indexable inserts with special profiles are available via the Walter Xpress system within four weeks.