www.industryemea.com

12

'26

Written on Modified on

Allied Vision Camera Enables 5,000 fps Synchrotron Imaging

Tohoku and Nishikyushu universities integrate high-speed CMOS platform for real-time 4D computed tomography and X-ray absorption analysis.

www.alliedvision.com

The “Hayaka” camera system enables the observation of ultra-fast structural changes and chemical state transitions. (Photo courtesy of Tohoku University)

High-speed X-ray imaging is increasingly required in materials science, battery research, and food engineering to observe structural and chemical changes under dynamic conditions. A research team from Tohoku University and Nishikyushu University has implemented this capability in its “Hayaka” 4D computed tomography system, built around the EoSens 1.1CXP2 CMOS camera from Allied Vision.

The lens-coupled X-ray imaging system is designed for time-resolved high-speed computed tomography (4D-CT) and X-ray absorption fine structure (XAFS) imaging using synchrotron radiation, combining microsecond exposure with multi-gigabit data throughput.

Imaging Fast Chemical and Structural Transitions

The Hayaka system targets applications where structural evolution and chemical-state transitions occur within milliseconds or faster. In synchrotron facilities, this includes dynamic materials testing, phase transitions, battery electrode reactions, and in situ food processing studies.

The system achieves a minimum exposure time of 1 µs and a maximum frame rate of 5,000 frames per second. This temporal resolution enables 4D-CT imaging, where three-dimensional structures are reconstructed continuously over time, supporting analysis of fast transient processes rather than static samples.

In XAFS mode, combined with high-speed energy scanning, the system captured complete spectral image datasets in 0.5 seconds. This supports time-resolved chemical state mapping, a key requirement in advanced battery and functional material research.

Optical Architecture for High Photon Throughput

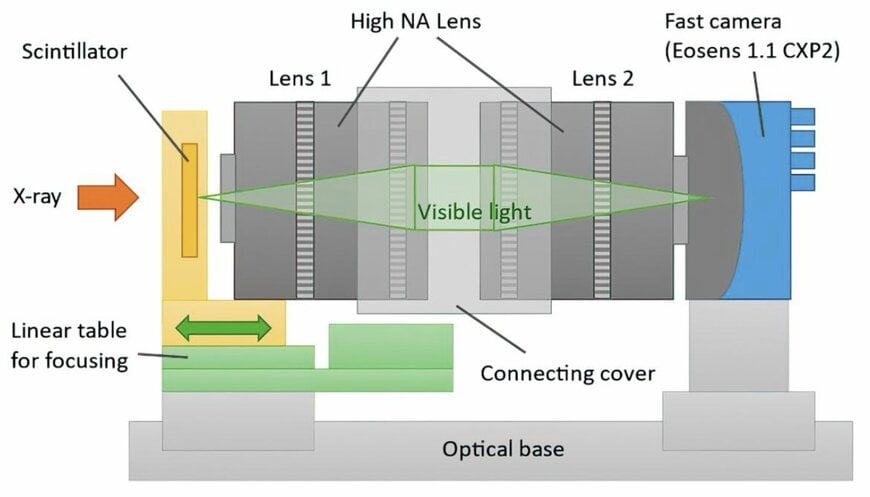

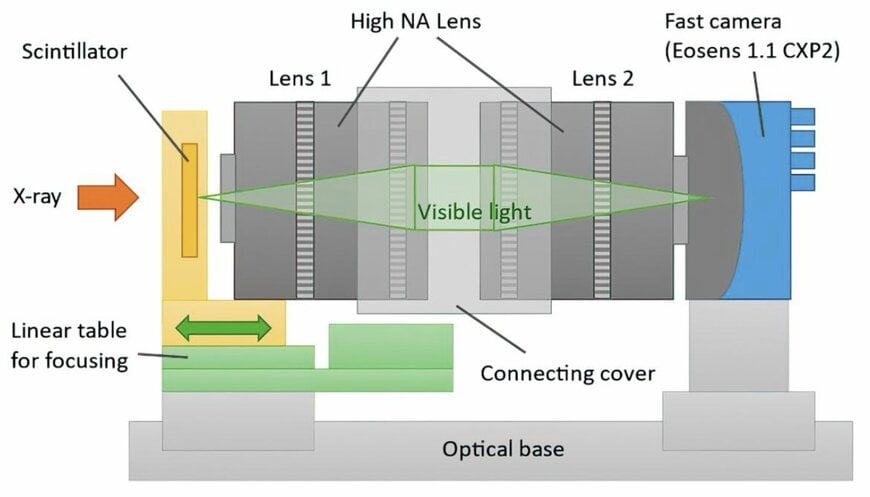

The imaging chain consists of five integrated components: a scintillator, a high-performance lens assembly, the CMOS camera, a precision focus mechanism, and a rigid mounting base.

Incoming X-ray photons are converted into visible light by the scintillator. The optical relay uses a back-to-back configuration of two high-numerical-aperture lenses, with their rear elements facing each other. This configuration increases light collection efficiency and optical throughput—critical for maintaining signal strength at microsecond exposure times.

Such lens-coupled architectures are often used when balancing spatial resolution, light efficiency, and mechanical flexibility in synchrotron-based X-ray imaging systems.

CMOS Platform and Data Throughput

At the core of the system is the EoSens 1.1CXP2 CMOS camera, equipped with a global shutter sensor delivering 1.1 megapixel resolution (1280 × 864 pixels), a 13.7 µm pixel size, and 10-bit depth stored as 16-bit. The camera operates at 3,660 fps at full resolution and reaches 5,000 fps at an 800 × 400 pixel region of interest.

Data transmission relies on a CoaXPress 2.0 interface using four channels with aggregate transfer rates up to 50 Gbit/s. This bandwidth allows sustained high-frame-rate acquisition without host-side bottlenecks, which is essential for synchrotron experiments where beam time is limited and data continuity is critical.

In feasibility studies using both white and monochromatic synchrotron radiation, the system achieved a spatial resolution of 77 µm at an exposure time of 10 µs. This demonstrates the ability to resolve fine structural details while freezing rapid motion.

Demonstrated 4D Imaging in Dynamic Processes

To validate the system under practical conditions, the research team combined the imaging setup with a high-speed rotation table. A boiling process involving Japanese noodles was recorded over 150 seconds with a temporal resolution of 0.5 seconds, producing time-resolved three-dimensional reconstructions.

This experiment illustrates how 4D-CT can be extended beyond conventional materials testing into food science and process engineering, enabling quantitative observation of internal structural evolution during heating and hydration.

Extending Toward Battery and In-Process Analysis

Further development focuses on time-resolved chemical state mapping inside battery electrodes during charging and relaxation. This will be enabled through synchronization between the imaging system and a germanium double-crystal monochromator, allowing controlled energy selection during high-speed acquisition.

In parallel, the team is developing an “in coquendo” 4D-CT configuration for real-time observation of cooking processes such as boiling, baking, steaming, frying, and microwave heating. These setups expand the role of synchrotron-based imaging within the broader materials and process research ecosystem, where combining structural tomography and chemical-state analysis in a single high-speed platform is increasingly required.

By integrating microsecond exposure capability, multi-gigabit data transfer, and optimized optical throughput, the Hayaka system demonstrates how high-speed CMOS imaging platforms can support next-generation synchrotron experiments requiring simultaneous spatial, temporal, and chemical resolution.

www.alliedvision.com

High-speed X-ray imaging is increasingly required in materials science, battery research, and food engineering to observe structural and chemical changes under dynamic conditions. A research team from Tohoku University and Nishikyushu University has implemented this capability in its “Hayaka” 4D computed tomography system, built around the EoSens 1.1CXP2 CMOS camera from Allied Vision.

The lens-coupled X-ray imaging system is designed for time-resolved high-speed computed tomography (4D-CT) and X-ray absorption fine structure (XAFS) imaging using synchrotron radiation, combining microsecond exposure with multi-gigabit data throughput.

Imaging Fast Chemical and Structural Transitions

The Hayaka system targets applications where structural evolution and chemical-state transitions occur within milliseconds or faster. In synchrotron facilities, this includes dynamic materials testing, phase transitions, battery electrode reactions, and in situ food processing studies.

The system achieves a minimum exposure time of 1 µs and a maximum frame rate of 5,000 frames per second. This temporal resolution enables 4D-CT imaging, where three-dimensional structures are reconstructed continuously over time, supporting analysis of fast transient processes rather than static samples.

In XAFS mode, combined with high-speed energy scanning, the system captured complete spectral image datasets in 0.5 seconds. This supports time-resolved chemical state mapping, a key requirement in advanced battery and functional material research.

Optical Architecture for High Photon Throughput

The imaging chain consists of five integrated components: a scintillator, a high-performance lens assembly, the CMOS camera, a precision focus mechanism, and a rigid mounting base.

Incoming X-ray photons are converted into visible light by the scintillator. The optical relay uses a back-to-back configuration of two high-numerical-aperture lenses, with their rear elements facing each other. This configuration increases light collection efficiency and optical throughput—critical for maintaining signal strength at microsecond exposure times.

Such lens-coupled architectures are often used when balancing spatial resolution, light efficiency, and mechanical flexibility in synchrotron-based X-ray imaging systems.

CMOS Platform and Data Throughput

At the core of the system is the EoSens 1.1CXP2 CMOS camera, equipped with a global shutter sensor delivering 1.1 megapixel resolution (1280 × 864 pixels), a 13.7 µm pixel size, and 10-bit depth stored as 16-bit. The camera operates at 3,660 fps at full resolution and reaches 5,000 fps at an 800 × 400 pixel region of interest.

Data transmission relies on a CoaXPress 2.0 interface using four channels with aggregate transfer rates up to 50 Gbit/s. This bandwidth allows sustained high-frame-rate acquisition without host-side bottlenecks, which is essential for synchrotron experiments where beam time is limited and data continuity is critical.

In feasibility studies using both white and monochromatic synchrotron radiation, the system achieved a spatial resolution of 77 µm at an exposure time of 10 µs. This demonstrates the ability to resolve fine structural details while freezing rapid motion.

Demonstrated 4D Imaging in Dynamic Processes

To validate the system under practical conditions, the research team combined the imaging setup with a high-speed rotation table. A boiling process involving Japanese noodles was recorded over 150 seconds with a temporal resolution of 0.5 seconds, producing time-resolved three-dimensional reconstructions.

This experiment illustrates how 4D-CT can be extended beyond conventional materials testing into food science and process engineering, enabling quantitative observation of internal structural evolution during heating and hydration.

Extending Toward Battery and In-Process Analysis

Further development focuses on time-resolved chemical state mapping inside battery electrodes during charging and relaxation. This will be enabled through synchronization between the imaging system and a germanium double-crystal monochromator, allowing controlled energy selection during high-speed acquisition.

In parallel, the team is developing an “in coquendo” 4D-CT configuration for real-time observation of cooking processes such as boiling, baking, steaming, frying, and microwave heating. These setups expand the role of synchrotron-based imaging within the broader materials and process research ecosystem, where combining structural tomography and chemical-state analysis in a single high-speed platform is increasingly required.

By integrating microsecond exposure capability, multi-gigabit data transfer, and optimized optical throughput, the Hayaka system demonstrates how high-speed CMOS imaging platforms can support next-generation synchrotron experiments requiring simultaneous spatial, temporal, and chemical resolution.

www.alliedvision.com