German manufacturer of railway washing systems positions itself for the future

Ratingen, Germany – 2nd of February 2026 With the support of Mitsubishi Electric and the engineering firm ATINA, German machine manufacturer BHB Waschanlagen Vertriebs GmbH has built a new tram washing system, designed to help save resources for Zurich’s public transport operator, Zürcher Verkehrsverbund.

emea.mitsubishielectric.com

The tram is parked in the wash hall for washing. The four wash cars move along the right and left sides of the vehicle.

Low-code programming and digital twins

“Customer demands for flexible, networked and resource-efficiency systems are increasing, especially amid the skilled labor shortages", says BHB managing director Tobias Straub. This means new digital concepts are required, he continues. Through Mitsubishi Electric and its Automation Network, we came into contact with the engineering firm ATINA, which has provided us with significant support in our digitalization efforts," Straub reports. "This enabled us to use a digital twin and the new low-code programming solution for the first time in the Zurich project."

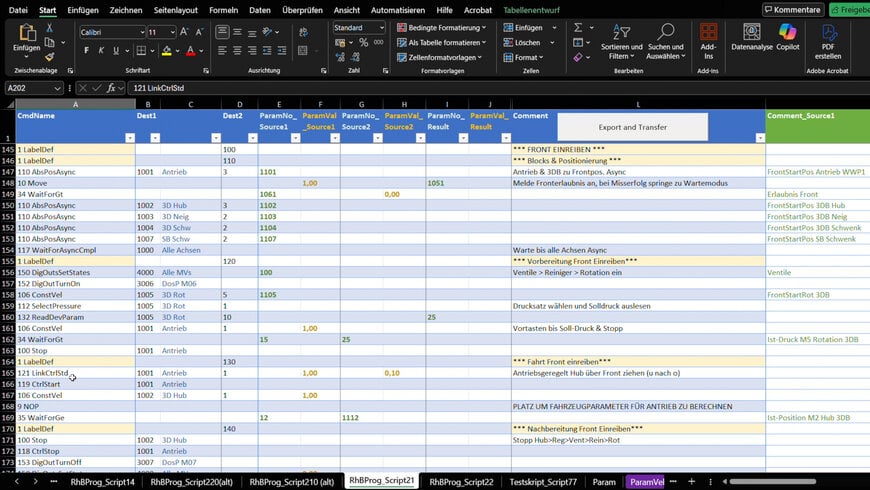

As a pure scripting language, ATINA's low-code programming eliminates the need for hard-coded, line-by-line programming. Washing programs can be easily parameterized using Excel spreadsheets, even without in- depth programming knowledge. This saves time, reduces sources of error, and facilitates subsequent revisions. With only 200 lines of text instead of 4,000, the programs are clearer and easier for service personnel to understand. The programs created in Excel can be transferred directly to the Mitsubishi control system via a simple CSV export.

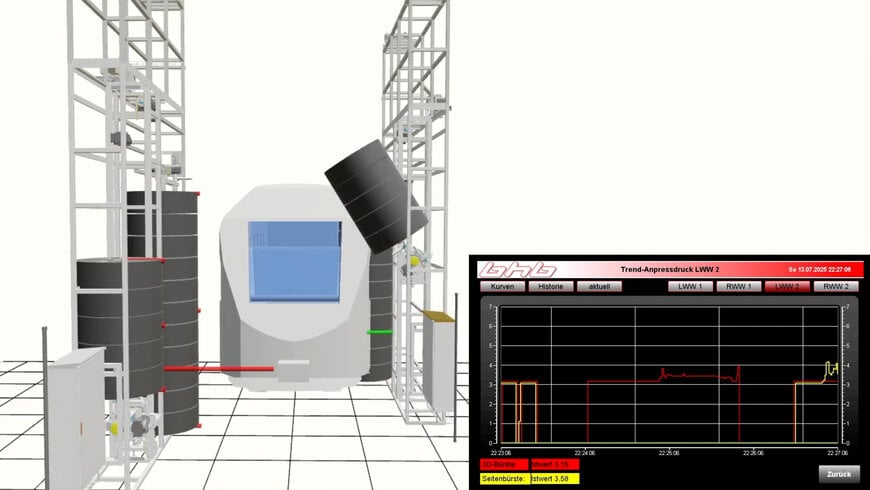

In addition to the script language, BHB used a digital twin for the first time for the Zurich project. All mechanical and electrical components of the washing system are stored there as fully functional 3D models and can be controlled by a real Mitsubishi Programmable Logic Controller (PLC). Since the programs can be tested very accurately at the desk, commissioning on site is greatly accelerated and virtually error-free – an enormous economic advantage for everyone involved, especially in more complex projects.

Thanks to a digital twin, the washing system can be thoroughly tested at the desk. This drastically reduces the commissioning time.

Innovation meets automation

However, digital twins and low-code programming alone would not have been enough to meet high customer requirements. That is why the software innovations are based on Mitsubishi Electric's reliable hardware. At the heart of the control system is the compact MELSEC FX5U-64MR/DS PLC. "Our hardware is exceptionally robust and backward compatible across generations," explains Michael Brandecker, a sales engineer at Mitsubishi Electric. "This enables machine builders, such as BHB, to offer their customers products whose components can be replaced after many years without costly reprogramming."

Additionally, Mitsubishi Electric drives ensure efficiency during operation. The FR-E800 series of frequency inverters enables flexible motor control, reducing energy and water consumption and contributing to economical and resource-efficient operation of the plant.

Mitsubishi Electric's FR-E800 series frequency inverters enable energy-efficient control of brushes and pumps.

Future-proof machine building requires digital transformation and the right partnerships

The BHB project serves as a model, particularly for medium-sized German machine builders. Thanks to close cooperation between partners who worked seamlessly together, the company successfully drove forward its digital transformation at the right time. BHB contributed its many years of experience in plant engineering, ATINA provided software expertise, and Mitsubishi Electric supplied robust automation components.

The result is a tram washing system that meets the growing demand for sustainability, quality, and efficiency while showing how medium-sized machine builders can remain competitive and attractive to skilled workers by using digital technologies.

The washing system and vehicles are precisely replicated in the digital twin. The virtual model is controlled by a real Mitsubishi Electric PLC to ensure realistic simulation.

Excel instead of code: There are 200 lines instead of 4,000. Thanks to low-code programming, washing programs no longer need to be hard-coded. All you need to do is fill in an Excel spreadsheet.

Partnership for success: Nawid Zarrabi from engineering firm ATINA, Tobias Straub from BHB, and Michael Brandecker from Mitsubishi Electric (from left to right).

About BHB

BHB Waschanlagen Vertriebs GmbH is a family-run company that has specialized in the manufacture and sale of washing systems and water treatment systems for rail vehicles (trains and trams) and commercial vehicles (buses and trucks) since 1983.

They offer high-quality system solutions, including washing chemicals and comprehensive after-sales service, worldwide. https://www.bhbwash.com/

About ATINA Engineering

ATINA Ingenieurbüro in Stuttgart has existed in its current form since 2010. With a focus on software and digital twins for the world of automation, the second generation of the company is responding to the growing importance of this topic in mechanical and plant engineering. The origins of the engineering office date back to 1982, when Reza Zarrabi founded ATINA Ingenieurbüro.

https://atina.de/de/unternehmen.