www.industryemea.com

02

'26

Written on Modified on

Dissipative Energy Chain for Cleanroom Applications

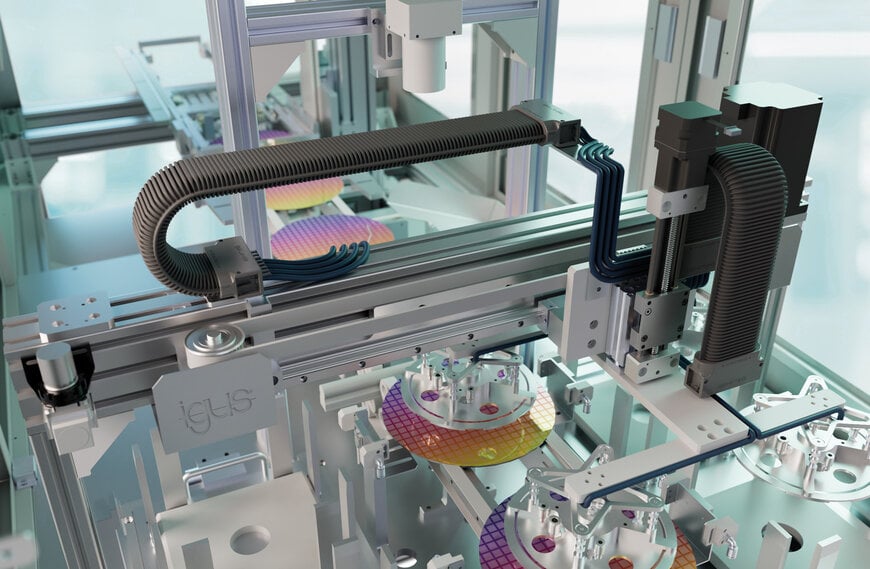

igus has introduced a compact, abrasion-resistant energy chain designed to meet electrostatic discharge and cleanliness requirements in semiconductor and battery production.

www.igus.eu

igus has released a new cleanroom-compatible energy chain that combines electrostatic discharge dissipation with abrasion resistance, targeting space-constrained cable guidance in semiconductor, electronics, and battery manufacturing environments.

Cleanroom requirements driven by electronics and battery production

The growing demand for lithium-ion batteries and semiconductor devices, driven by electric vehicle adoption and AI-related computing, is increasing the sensitivity of production environments. Manufacturing equipment used near wafers, chips, and battery cells must limit particle emission and prevent electrostatic discharge (ESD), which can damage sensitive components even at levels not perceptible to operators.

Cable guidance systems are a critical part of this environment. Conventional power and data cables are typically not dissipative, requiring additional shielding or increased distance from the product. Both approaches consume valuable cleanroom space and can complicate machine design.

Dissipative and abrasion-resistant material concept

The newly introduced energy chain addresses this challenge by integrating ESD-dissipative properties directly into the chain material. Additives within the high-performance polymer enable controlled dissipation of electrostatic charges through the mounting brackets, providing a defined discharge path without the need for external shielding measures.

At the same time, the material is designed for high abrasion resistance. Reduced wear is essential in cleanroom systems, as particle generation from moving components can compromise air quality and product yield. The combination of dissipative behaviour and low abrasion targets use in close proximity to sensitive products.

Compact geometry and mechanical performance

The energy chain uses a closed-pipe design formed by upper and lower shells, enclosing cables and media lines to prevent particle escape. Its compact form factor supports tight bend radii down to 55 mm, allowing routing in confined installation spaces.

Depending on the configuration, the chain provides inner heights between 20 mm and 40 mm and inner widths from 33 mm to 85 mm. An oval cross-section and defined stiffness enable unsupported lengths, eliminating the need for additional guide troughs that would otherwise increase system complexity and footprint.

From a lifecycle perspective, the chain is specified for more than 20 million double strokes, indicating suitability for high-duty-cycle automation systems in continuous production environments.

Cleanroom qualification and testing

The system is designed to meet the most stringent cleanroom requirements, up to ISO Class 1. High abrasion resistance limits particle generation during dynamic motion, while the closed-shell construction prevents particles released from internal cables from escaping into the surrounding environment.

Cleanroom performance has been validated in igus’ in-house cleanroom laboratory in Cologne, developed in cooperation with the Fraunhofer Institute for Manufacturing Engineering and Automation. Testing focused on particle emission under motion, with results confirming suitability for high-purity manufacturing applications.

Application relevance

By combining ESD dissipation, compact dimensions, and cleanroom compatibility, the energy chain is intended for use in semiconductor fabrication tools, battery cell production equipment, and electronics assembly systems. Its design addresses the need to route power, data, and media close to sensitive products while maintaining cleanliness, safety, and mechanical durability within advanced manufacturing environments.

www.igus.eu