Flexxbotics Releases Free Software-Defined Automation Platform for Manufacturing Autonomy

Production-grade automation software enables open, interoperable, and autonomous factory operations worldwide.

flexxbotics.com

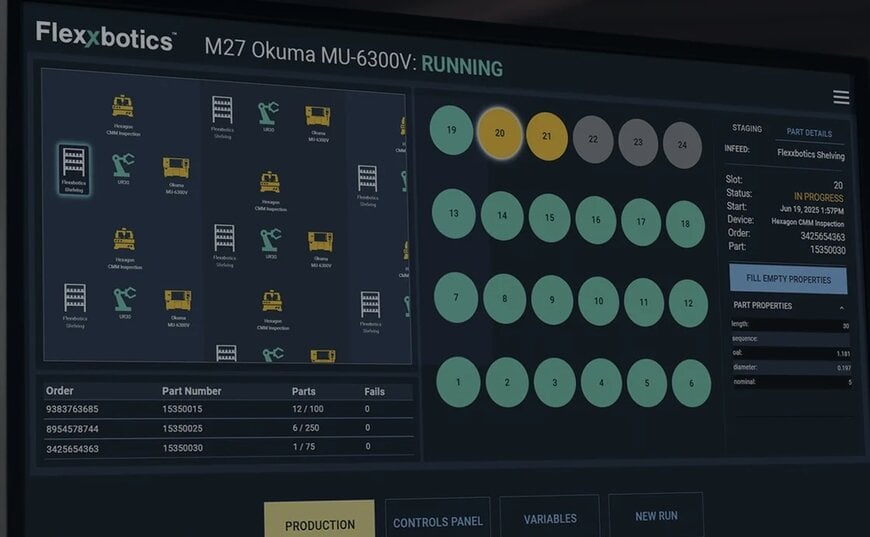

Flexxbotics has announced the general availability of its software-defined automation (SDA) platform as a free software download, giving manufacturers, system integrators, and automation engineers direct access to industrial-grade automation technology used in live production environments.

The free download is not a trial or evaluation version. It includes the full SDA runtime environment, low-code human–machine interface (HMI), developer studio, and complete API—without time limits, capacity restrictions, or disabled features. The platform is designed to support production deployment from day one, enabling scalable autonomy across advanced manufacturing operations.

Software-defined automation built for real factories

Flexxbotics’ SDA platform is engineered for fault-tolerant stability, cybersecurity, and regulatory compliance. Its browser-native frontend uses progressive web application technology with hardened access controls, while a lightweight, containerized backend runs on virtually any compute infrastructure. This architecture allows manufacturers to deploy automation consistently across plants while maintaining deterministic performance and security.

A core capability of the platform is many-to-many controller interoperability. Flexxbotics connects more than 1,000 makes and models of industrial equipment, eliminating the need for complex, custom point-to-point integrations. Through parallelized data pipelines, the platform enables real-time, bidirectional data flows across heterogeneous factory assets—including machines, PLCs, robots, test systems, and IT platforms—using both open and proprietary industrial protocols.

Designed for autonomy, AI, and compliance

Flexxbotics targets manufacturers pushing beyond traditional automation limits. Key use cases include automated sequencing across multiple machines, sovereign data acquisition for Industrial AI training, contextualized data capture for regulatory compliance, and closed-loop autonomous process control.

Automation and controls engineers can deploy prebuilt controller drivers—called Transformers—or develop their own using Python. Each new driver inherits compatibility with all others in the system, enabling rapid expansion of interoperable factory control.

According to Flexxbotics, this architecture accelerates equipment connectivity by up to 22× compared with conventional PLC-based integration approaches, while providing the data foundation needed for Physical AI and autonomous optimization.

Key capabilities included in the free download

- Universal open connectivity across major industrial protocols and controllers

- High-frequency, multi-source data acquisition for Industrial AI training

- Rule-based and conditional cell automation for dynamic sequencing

- Closed-loop autonomous process control with real-time feedback

- Digital thread traceability supporting standards such as ISO 13485, CGMP, and AS9100

- Python-based developer studio with REST APIs for bring-your-own AI models

The platform operates both online and offline, ensuring production continuity even without internet connectivity, and integrates with existing enterprise systems such as ERP, MES, QMS, PLM, CAD/CAM, and SCADA.

Availability

The Flexxbotics software-defined automation platform is available for immediate download and includes the full production-ready feature set.

www.flexxbotics.com