www.industryemea.com

21

'25

Written on Modified on

ZEISS unveils new quality software for inspection and data analysis

ZEISS INSPECT and PiWeb 2026 R1 enhance quality control with new features like AI-powered report translations and volume data insights.

www.zeiss.com

ZEISS Industrial Quality Solutions (ZEISS IQS) announces the latest software updates for ZEISS INSPECT and ZEISS PiWeb, addressing the growing challenges of industrial quality control. By providing holistic solutions ZEISS IQS enables end-to-end inspection processes and streamlined workflows. The 2026 software release delivers innovative tools to help manufacturers manage complexity, boost efficiency, and stay competitive.

ZEISS INSPECT 2026: Redefining optical and X-ray inspection

Industrial quality control today requires solutions that ensure compliance, reduce manual effort, and improve inspection accuracy. ZEISS INSPECT 2026 meets these demands, for example with advanced GD&T functionality that ensures compliance with the latest standards, seamless CAD compatibility, and faster scripting. Offline access to the ZEISS Quality Tech Guide ensures users always have critical knowledge at their fingertips.

Building on this foundation, the release introduces innovations that simplify complex tasks, enhance reliability, and boost efficiency across X-ray and optical workflows, empowering users to achieve superior quality results with greater ease and confidence.

ZEISS INSPECT X-Ray: Unlocking new possibilities for volume data

Key innovations include automatic brightness and contrast adjustment, the export of sectional views as videos or image stacks, multi-part separation, flexible licensing options, and support for all ZEISS METROTOM systems.

ZEISS INSPECT 2026: Redefining optical and X-ray inspection

Industrial quality control today requires solutions that ensure compliance, reduce manual effort, and improve inspection accuracy. ZEISS INSPECT 2026 meets these demands, for example with advanced GD&T functionality that ensures compliance with the latest standards, seamless CAD compatibility, and faster scripting. Offline access to the ZEISS Quality Tech Guide ensures users always have critical knowledge at their fingertips.

Building on this foundation, the release introduces innovations that simplify complex tasks, enhance reliability, and boost efficiency across X-ray and optical workflows, empowering users to achieve superior quality results with greater ease and confidence.

ZEISS INSPECT X-Ray: Unlocking new possibilities for volume data

Key innovations include automatic brightness and contrast adjustment, the export of sectional views as videos or image stacks, multi-part separation, flexible licensing options, and support for all ZEISS METROTOM systems.

- Automatic brightness and contrast adjustment: Enhance visual inspections with a single click. Easily optimize brightness and contrast for selected areas in multiview images, ensuring fast and clear visualization for multi-material datasets.

- Export section views as videos or image stacks: Share insights effortlessly by exporting section views in widely used formats, making results accessible without specialized software.

- Multi-part separation: Automatically split batch scans into stages for streamlined multipart inspections, simplifying workflows and improving reporting for batch scans.

- Flexible licensing options: Tailor licenses to specific needs, such as visual inspection, dimensional metrology, or nondestructive testing, for a cost-effective approach to 3D X-ray inspections.

- Support for all ZEISS METROTOM systems: Seamlessly integrate powerful data acquisition features, data analysis, and reporting into a single workflow for all ZEISS METROTOM systems, including the new METROTOM 800 320kV, reducing complexity and ensuring high-quality results.

ZEISS INSPECT Optical 3D: Smarter scanning and inspection

Key innovations include surface-based decalibration check, enhanced capabilities for ZEISS T-SCAN hawk 2, and an eMotor Stator Inspection App.

Key innovations include surface-based decalibration check, enhanced capabilities for ZEISS T-SCAN hawk 2, and an eMotor Stator Inspection App.

- Surface-based decalibration check: A new method ensures reliable sensor calibration during scanning, overcoming limitations of reference point-based checks and eliminating false positives caused by poor point distribution.

- Enhanced capabilities for ZEISS T-SCAN hawk 2: Adaptive resolution enables on-the-fly switching between resolutions, while improvements in meshing and extended measurement volume support enhance scanning efficiency and quality.

- eMotor Stator Inspection App: This new app simplifies hairpin assembly evaluation for stators, measuring features like creepage distance and air distance with precision. Developed especially for the use with ZEISS ScanBox 4105 for eMotors, the app ensures repeatable processes and reduces manual effort.

ZEISS PiWeb: Revolutionizing data analysis and efficiency

ZEISS PiWeb 2026 R1 is the latest evolution in quality data management software, designed to elevate data analysis workflows and enhance user productivity. This release introduces cutting-edge features that empower teams to work smarter, collaborate seamlessly, and make informed decisions with greater ease.

Key innovations include augmented 3D CAD visualization, AI-Powered report translations, effortless table creation, customizable notifications, and Dark Mode.

ZEISS PiWeb 2026 R1 is the latest evolution in quality data management software, designed to elevate data analysis workflows and enhance user productivity. This release introduces cutting-edge features that empower teams to work smarter, collaborate seamlessly, and make informed decisions with greater ease.

Key innovations include augmented 3D CAD visualization, AI-Powered report translations, effortless table creation, customizable notifications, and Dark Mode.

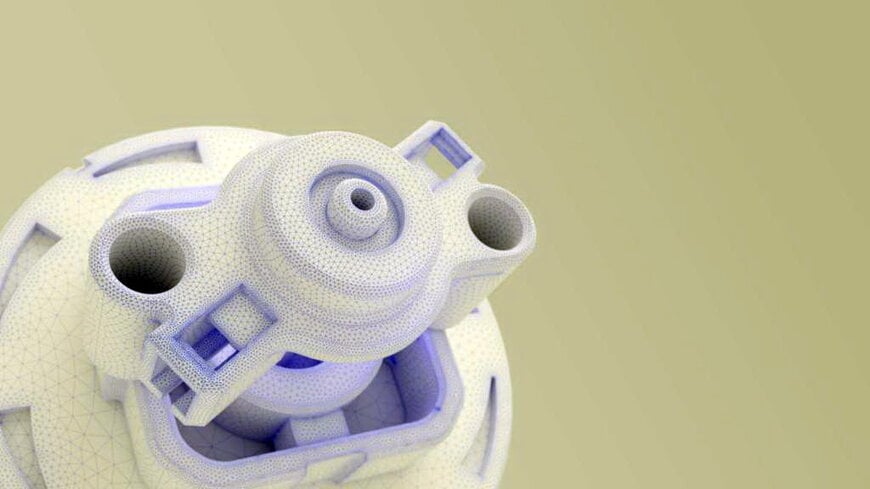

- Augmented 3D CAD visualization: All ZEISS INSPECT and ZEISS CALYPSO users can now embed form plot data and mean values directly into the interactive CAD view, simplifying data interpretation and enabling more intuitive analyses. Optimized data storage reduces loading times and ensures a smoother workflow.

- AI-Powered report translations: With your preferred GenAI engine, reports are instantly translated into the user’s preferred language, eliminating manual efforts and enhancing global collaboration.

- Effortless table creation: ZEISS PiWeb Designer now supports the creation and optimization of tables, offering extensive customization options. Centralized template storage on the server enables streamlined teamwork via the Monitor browser app.

- Customizable notifications: Users gain improved control over email alerts, ensuring they stay informed about critical measurements and urgent tasks without unnecessary distractions.

- Dark mode: This new display option reduces eye strain during extended work sessions, improving readability in low-light environments and offering a tailored user experience.