www.industryemea.com

02

'25

Written on Modified on

Swanline achieves world-first with BOBST Connect across mixed equipment

The company connected multiple BOBST machines, including retrofitted older ones, and a non-BOBST die-cutter, enabling analogue signal translation to digital data.

www.bobst.com

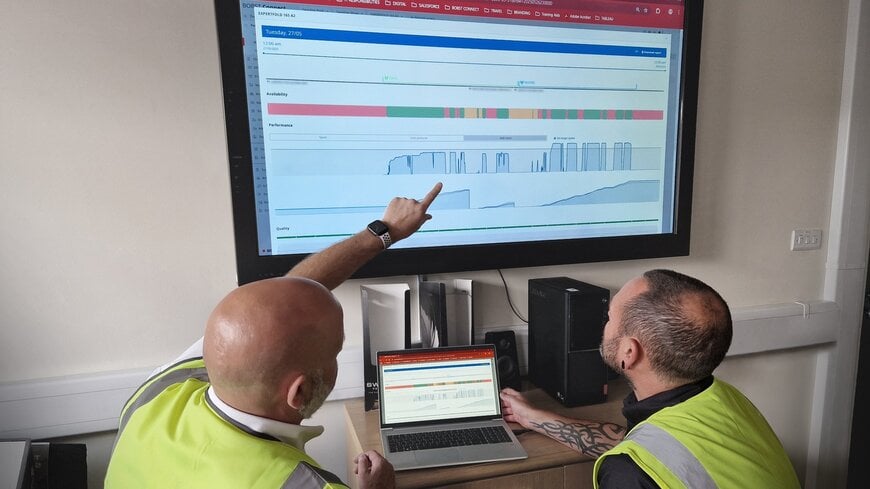

BOBST Connect combines data and digital services into a single, fully connected platform, providing a real-time overview and management of a company’s production process. It integrates raw machine data with BOBST knowledge and expertise to improve printing and packaging productivity.

Swanline’s integration demonstrates that the BOBST Connect platform can be implemented across BOBST and non-BOBST machines alike. The company has connected its two BOBST VISIONCUT 1.6 die-cutters and BOBST EXPERTFOLD 165 folder-gluer, along with a BOBST laminator and a non-BOBST die-cutter. Importantly, two of the oldest machines have been retrofitted with novel BOBST technology enabling the machines’ analogue signal to be translated into digital data.

Chris Brown, MD Swanline Group, said: “By capturing and interpreting data across a broader range of equipment, we’ll be able to optimize processes that were once based purely on experience or assumption. It’s a big step toward building a more connected, responsive and data-informed manufacturing environment. This opens up exciting potential to bring a new level of intelligence to areas of the business that previously operated without that kind of visibility.

We chose to use BOBST Connect as part of our broader strategy to drive smarter, more efficient and data-led manufacturing across the business. As a trade-only supplier, our customers rely on us to deliver with precision, consistency and speed, and having clear visibility over our production data is essential to achieving that. Ultimately, our decision to adopt BOBST Connect is about staying ahead, giving our teams the information they need to work more efficiently, more precisely and with greater confidence.”

BOBST Connect is designed to improve packaging and printing productivity via improved planning, better-informed decision-making, faster and more effective intervention, and continual optimization. As a cloud-based platform, users can connect to the system through any internet-enabled device.

The BOBST Connect package offers priority remote technical support including video-enabled assistance to help diagnose faults and issues faster. In addition, Swanline has added energy monitoring tools to two of its connected machines, enabling the production team to correlate energy usage with production data.

www.bobst.com