REDEX Group plans and installs side trimmer at Arcelor Mittal Bremen

Galvanized hot-rolled strip - perfectly trimmed.

www.redex-group.com

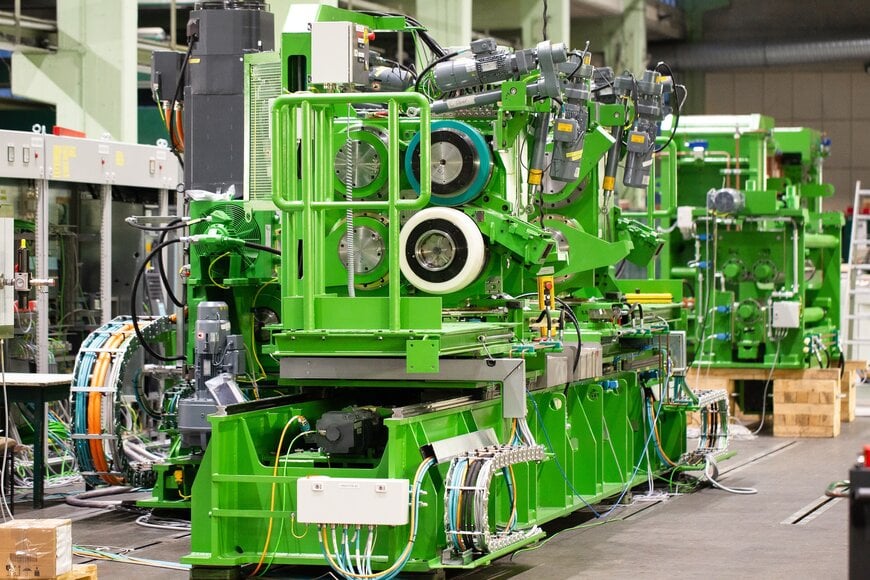

At Arcelor Mittal's Bremen steelworks, a new side trimmer line is being used to precisely trim galvanized hot-rolled strip. One of the challenges that had to be overcome during project planning was the lack of space for the installation: The trimmer line had to be located above the galvanizing line. This is unusual, but it has yielded a space-saving and elegant solution. The plant is already in operation and produces trimmed sheet steel with thicknesses of 0.6 to 6.3 mm in high quality.

The steel industry has a long tradition in Bremen from production to processing, as well the consumption of steel in the shipyards for example. As a production site, the Arcelor Mittal steelworks represent a symbol of this tradition. Founded in 1957 and part of the Arcelor Mittal Group since 2007, the site which extends over an area of around 7 km2, can produce up to 3.5 million tons of crude steel per year. Arcelor Mittal’s integrated steel mill in Bremen produces flat steel products for the automotive industry, building construction, mechanical engineering, the household appliance industry and tube production, among others. The product range also includes hot-dip galvanized sheet.

The requirement: retrofitting a trimming station for galvanized sheet metal

As part of its ongoing investment in plant optimization, Arcelor Mittal commissioned REDEX GmbH with the task of installing a trimming line at the exit of their Bregal 2 hot strip hot-dip galvanizing line, which had been commissioned in 2001 and which processes sheet thicknesses from 0.6 to 6.3 mm. The aim of this project was to produce higher-quality sheets with trimmed strip edges - in exactly the strip width required by the user and at a production speed of up to 120 m/min.

The challenge: structural constraints

The REDEX Group is familiar with such a task because in 2020 REDEX took over a team from Duisburg-based BGW, which was a leading specialist in rolling mill plant technology. The company - now part of the REDEX Group - also has extensive experience in the planning and installation of trimming systems.

One challenge that required a high level of experience and expertise was the structural environment. The floor plan of the complete galvanizing plant could not be extended, so that only one option was possible: The existing line had to “go up a level”, so to speak - with the trimming line on top, on a newly built platform. This in turn required a change to the belt run and the relocation of installed units - taking into account the maximum possible construction height. And the trimming system had to be installed on a structural steel platform, which was supported by the existing steel structure.

From the basement to the top platform: redesigned coil path

The new path of the galvanized coil now begins with a pilot roller in the basement of the line, which is installed in the same place as the previous deflection roller and guides the strip vertically upwards through the existing marking machine.

A tension roller set increases the belt tension and guides the belt horizontally into a double control roller. From there, the belt runs centrally through the side punch into the trimming unit. After the belt has been trimmed, it is conveyed vertically via a deflection roller through the vertical inspection and then through a further set of tensioning rollers to then reach the horizontal belt run area in front of the recoiler.

High cutting quality thanks to elaborate shear design

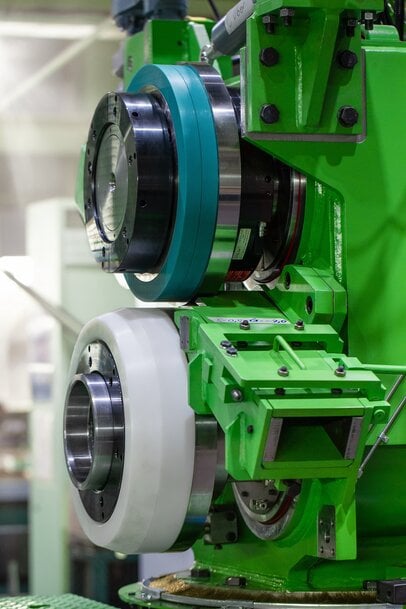

Trimmer machines from REDEX (or formerly from BWG) can be equipped with rotary head trimming shears if required. The trimming shears are equipped with two roller knives with a thickness of 40 mm and a diameter of 450 mm, which are arranged offset one above the other.

This type of shear achieves a highly accurate cutting width with minimal burr formation and very low blade wear. This is ensured, among other things, by a horizontal and vertical blade gap adjustment system that optimizes the quality of the cut edges. With this system, the cutting gap can be freely adjusted depending on the thickness and quality of the material. The upper and lower knives are arranged so that the hem strip is directed downwards into hardened guides that guide it into a scrap chopper.

Adjusting devices: high performance drive and control technology

The system operates with a high degree of reliability and enables a permanently high line capacity. It is not necessary to readjust the cutting gap after a knife change. The width is adjusted via a speed-controlled three-phase servo motor. It drives two backlash-free, counter-rotating ball screws, which are arranged in opposite directions.

The gap is set by an electromechanical actuator - an electric cylinder - which moves the bottom blade axially. The spindle is adjusted with low backlash by two threaded nuts arranged against each other. The speed-controlled geared motor to the electric cylinder is equipped with an encoder for gap positioning. This design ensures that a longer cylinder stroke is translated into the movement of the fine gap adjustment - this produces high accuracy. A high-precision electromechanical actuator is also used to adjust the overlap.

Side punch for coil change

An important function in the trimming process is performed by the side punch, which is used when setting the edging shears to a new width after a coil change. During this process step, the knives must not be engaged in the strip. The side punch therefore punches out larger areas at the connection between the old and new strip. The strip is then moved into the trimming shears up to the punched-out area. The knives are now free, and the trimming shears can automatically move to a new width. The system processes belts with widths from 600 to 1800 mm, the width of the edging strip can vary from 6 to 100 mm.

The scrap from the sidepunch is fed to the scrap conveyor belt via a short conveyor belt. All the scrap is transported to the adjacent hall via a conveyor belt and discharged there via an adjustable chute into one of two scrap containers.

High quality, high flexibility

The fully automated trimming process also makes the process of changing coils highly efficient. The integrated sensor technology, in the high-precision strip width measurement (+/- 0.2 mm) for example, is a key contributor to the precise cutting results. Also worth mentioning here is a new strip tension measurement system, which was installed as part of the retrofit.

Automation and operation

At the control level, the trimming system is integrated into the largely automated galvanizing line. The display and operating technology in the control room has been expanded accordingly, including a visualization station. During manual operation, several local consoles and control stations with a direct view of the process can be used. And, of course, the REDEX designers have met all the normative requirements for noise protection and machine safety. The system has now been put into operation and is running to the complete satisfaction of the operator.

www.redex-group.com