www.industryemea.com

04

'19

Written on Modified on

With Nidec Leroy-Somer, Ahlstrom-Munksjö consolidates its attachment to the local economy and wins export markets

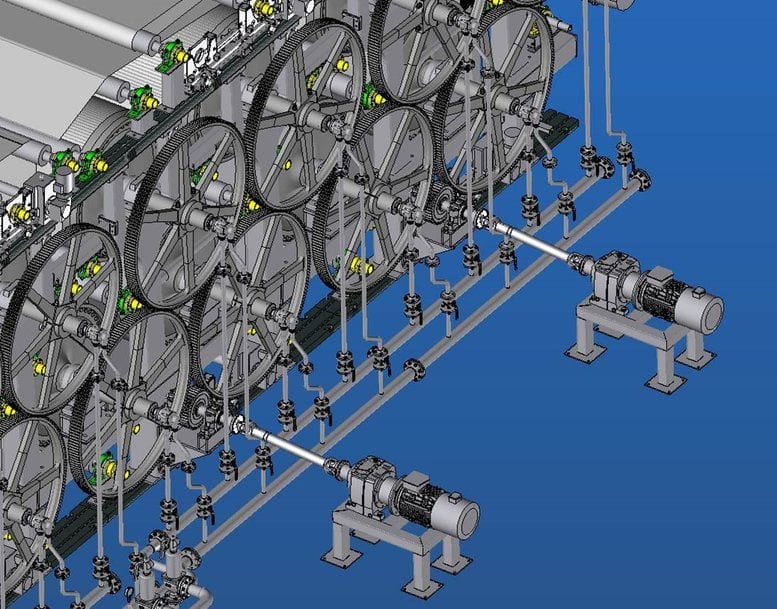

Meeting market expectations… keeping at the head of the pack of innovators in its field… always serving its customers better. To keep pace with its order book and pursue its development, the Ahlstrom Specialties plant at Saint-Séverin in Charente has recently been expanded. This allows it to play its part fully in the dynamics of its employment catchment area. The plant today comprises four complete manufacturing lines, and all four are comprehensively equipped with Nidec Leroy-Somer motors. Let us consider why.

Ahlstrom-Munksjö produces fibre-based materials and special innovative and ecological papers. It is the leading industrial group in its field, with its HQ in Finland. The group employs 8000 members of staff and operates 45 production units in 14 countries.

In France, its Saint-Séverin site (in the south of the Charente department) specialises in the production of parchment paper. The site is indeed the world leader in its field. Its main clients are principally to be found in the sectors of the food industry, electronics and aeronautics, offering rapidly expanding markets for this plant, which exports the world over.

Giant-sized…

To set the scene, picture a rectilinear machine, several meters wide, several meters high, and around 100 meters long. At one end of the machine you have a spool unwinder from which emerges a strip of paper two to three meters wide, and measuring just several tens of microns thick. This strip of paper then passes between hundreds of steel rollers, which convey the paper strip while ensuring that it remains at the correct tension right along the production line. As it zigzags through the machine, the paper strip covers a total distance of more than 200 meters, moving at a speed of several meters per second.

Without going into detail in this article, suffice it to say that from the sheet being unwound at the start of the line to being wound onto a drum at the end of the line the paper travels, in the course of manufacture, at very high speed between the steel rollers (situated transversally the length of the machine) through 4 production stations aligned over a distance of around 100 meters (coating, drying, finishing, winding). In this enormous machine, the transverse rollers serve to propel the paper strip and regulate its tension (it must not be torn) along a perfectly managed production run.

… with real finesse

Needless to say, the perfect synchronisation of the rotation of these rollers is one of the keys to success. The slightest unexpected speed deviation with a single one of these rollers would cause the paper strip in production to tear, with a major impact on the production costs. In short, to manufacture high-quality, hi-tech paper it takes fine-scale control, in the very heart of the machine while manufacturing progresses, of parameters such as humidity level and porosity. Just as important is to ensure the highest operational uniformity of the motors and geared motors involved in rotating the drive rollers.

Maintaining control over your production facilities

The Ahlstrom Specialties plant has chosen to design and manufacture its machines itself, and to draw on local players in this endeavour. "We take great care with the quality of our products and with controlling our costs," explains Gérard Giry, Maintenance and Engineering Manager at Ahlstrom Specialties. He adds: "We need to have complete control over our production line." As is the case in so many extremely specialised or sensitive fields, developing your machines on site is an efficient way of maintaining control over your production facilities, so as to ensure effective management of their maintenance, or for developing innovation, not to forget the ability to ensure that your manufacturing secrets are kept under wraps.

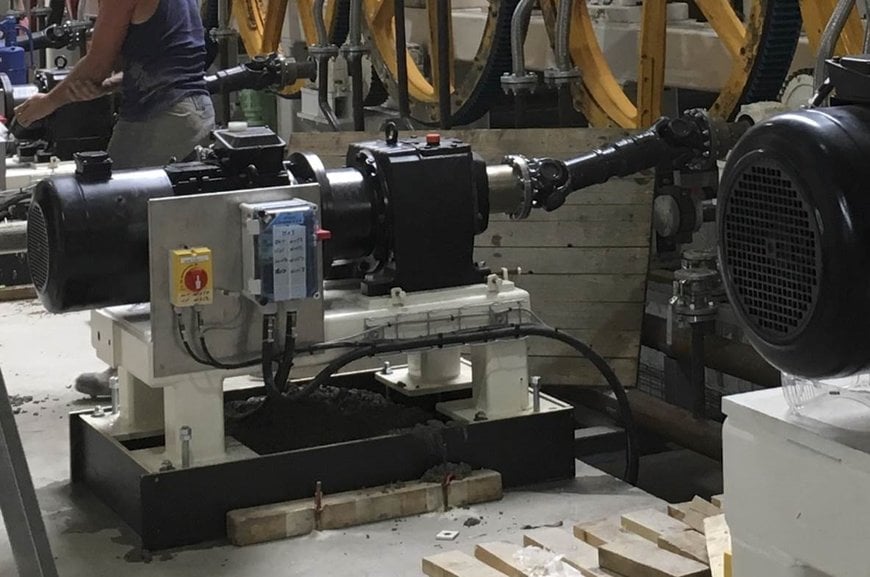

And this is where Nidec Leroy-Somer comes in. It brings to the table, of course, the technical performance of its electromechanical drive solutions (in particular the CB3000 range of geared motors on the new, recently commissioned production line). Yet the engineers of Ahlstrom-Munksjö also selected this manufacturer for its reactivity.

Of course, the reputation of its local partner, SEFI, the French distributor specialised in the field of power transmission, weighed significantly in its favour, with its well-established reputation in the factory environment, in dealings with new works & maintenance managers, and with production managers. It should also be pointed out that the efficiency of the Nidec Leroy-Somer Assembly Centre is recognised in the profession. The service proposed – which incidentally has no equivalent on the market – allows this manufacturer of electric motors and alternators to support its clients, partners and distributors with the service that the latter themselves provide daily to users.

"To guarantee the care and attention that we wish to offer our clients," says Mr Giry, "we need to be able to count fully on our suppliers." He adds: "Since becoming a part of Nidec, Leroy-Somer has been able to demonstrate even more attentiveness to the express needs of its clients."

Gérard Giry, Maintenance and Engineering Manager at Ahlstrom Specialties

"The manufacturing of high-quality, hi-tech paper requires us being able to guarantee high precision in the automation systems, on the scale of our machines, combined with great finesse."

The paper manufacturing principles are well known. In the course of its production, a 2.5 m-wide strip of paper passes through four broad stages: coating, drying, finishing, rolling. This strip of paper goes through the various stages on its production line over a distance of around 100 meters. The paper sheet (200 meters long) enters this line at one end. An enormous roll of paper (weighing some 3 tonnes) is wound in at the other end (35 km of paper per drum). In all, it takes dozens of rotation axes that need to be controlled with the highest degree of finesse and synchronisation. The drive rollers (there are approximately 180 on the line) must all guarantee the same travel speed for the paper to prevent it tearing.

About the technical solution

Compabloc 3000 geared motors with parallel gears from Nidec Leroy-Somer are used to adapt the speed of the electric motor to that of the driven machine. The full range comprises 10 different sizes. Among the technical characteristics of this family of geared motors, the following in particular stand out: a rated output torque of between 10 N.m and 14,500 N.m, a power output ranging from 0.06 to 110 kW, reduction ratios of between 1.16 and 252, and high efficiency of between 95 and 98%. It should also be noted that these geared motors are reversible. This equipment is also appreciated for its quiet running.

For more than a century, the manufacturer's solutions have been present in every industry where energy needs to be produced and movement transmitted. Backed by this wealth of experience, the engineers and technicians of this French company provide innovative and reliable solutions for the most varied of applications. What is more, thanks to its design offices, it is able to work alongside its customers in the heart of their business from the earliest design stages of the applications and products. In this way, Nidec Leroy-Somer can adapt and customise its product ranges by incorporating the requirements of the customer specifications or processes (control, self-diagnostic, communication, automation, monitoring, etc.), the requirements of the working environment (humidity, corrosion, high temperature, explosive atmospheres, etc.), the machine function constraints (handling, pumping, compression, ventilation, etc.), and the industrial standards and norms (chemicals, automotive, food, paper, naval industries, etc.). Nidec Leroy-Somer has developed new technologies for machine cooling, high speeds, electromagnetic compatibility, reduced noise and vibrations, surface treatment, mechanical resistance of materials, and the coating and insulation of windings, to constitute an incomparable wealth of solutions.

www.leroy-somer.com

www.ahlstrom-munksjo.com

www.sefitransmission.fr