Layer by Layer: IDS Cameras Advance Precision Monitoring in Additive Manufacturing

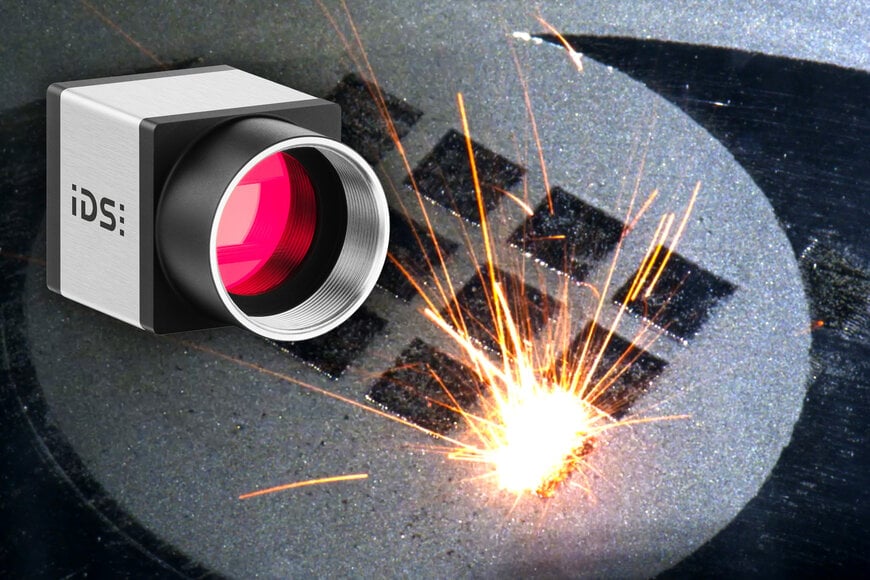

At Aalen University’s LaserApplicationCentre, IDS industrial cameras enable high-speed, high-resolution observation of PBF-LB/M processes — improving defect detection, material research, and process optimisation.

en.ids-imaging.com

Powder bed-based laser melting of metals (PBF-LB/M) is a key technology in additive manufacturing that makes it possible to produce highly complex and high-performance metal components with customised material and functional properties. This technology is used in numerous industries - from aerospace and medical technology to the automotive industry - and is considered groundbreaking for the manufacturing of the future. Advances in process monitoring and control are crucial to further increasing the quality, reproducibility and efficiency of this manufacturing process.

A key challenge is the precise analysis of the layer-by-layer laser melting process, as this has a decisive influence on component quality. As part of research into increasing process stability and efficiency, students and scientific staff at the LaserApplicationCentre (LAZ) at Aalen University are conducting global, dynamic observation of the PBF-LB/M process. In the context of high-speed process control with temperature feedback, phenomena such as spatter and smoke formation, solidification behavior, and the safe movement of mechanical components during additive manufacturing are investigated. This is supplemented by a high-resolution, static analysis of the remelted component layer geometries and precise detection of potential defects in the powder layers in order to be able to draw well-founded conclusions about the resulting component quality. The imaging components of the research project are two high-performance USB3 industrial cameras from IDS Imaging Development Systems.

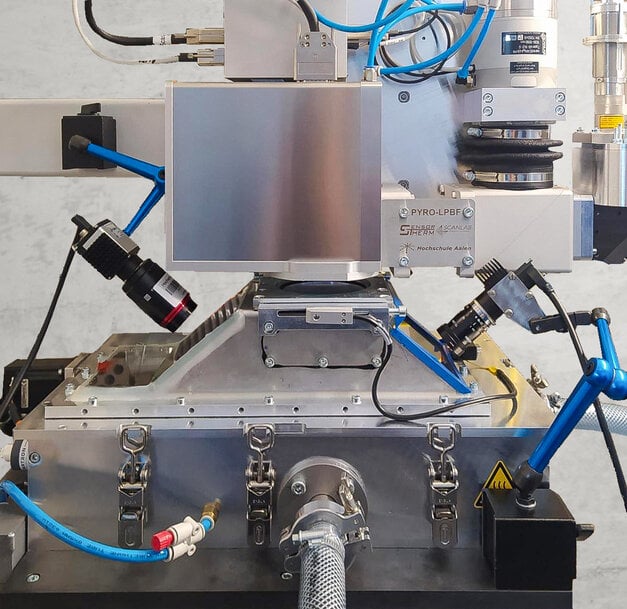

Test setup for additive manufacturing with the IDS camera U3-3040CP-C-HQ Rev.2.2 and the IDS camera U3-3990SE-M-GL Rev.1.2.

Two IDS industrial cameras provide the necessary image information

The two different tasks require different camera models. "We use a model from the USB3 uEye CP camera family for the global, dynamic observation of the PBF-LB/M process, such as splashes or the formation of smoke. A USB3 uEye camera from the SE series is used for the static, high-resolution identification of anomalies within the powder layers and in the remelted component layer geometries," explains David Kolb, research associate at the LAZ.

Requirements for the camera systems

The requirements for the two IDS camera systems are different due to their areas of application in the PBF-LB/M.

"Since powder bed-based laser beam melting of metals is a highly dynamic additive manufacturing process in which the component is generated layer by layer, the following features were particularly important for global, dynamic monitoring: The camera must offer a resolution of more than 1000 x 1000 pixels and a frame rate of more than 100 fps, cover an image field of at least 100 mm x 100 mm and have a trigger port for video recordings," says David Kolb, explaining the choice of camera model. The selected U3-3040CP-C-HQ Rev.2.2 enables excellent image quality even in low light or when the camera should take pictures of fast-moving objects. The integrated IMX273 global shutter CMOS sensor from Sony's Pregius range scores particularly well for its image quality, high sensitivity and wide dynamic range. With a resolution of 1.58 megapixels (1456 x 1088 px), it achieves a frame rate of 251 frames per second - ideal for detailed video and image analyses of dynamic processes.

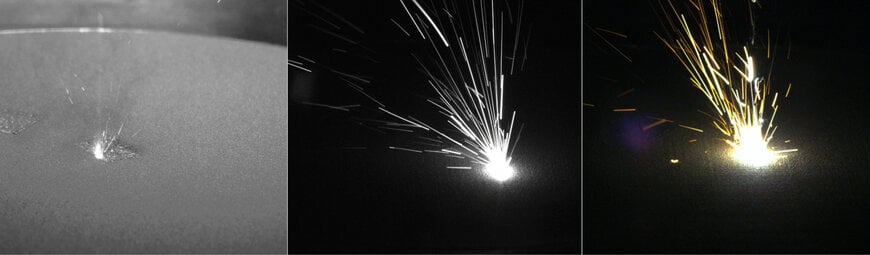

Global process monitoring of the PBF-LB/M with different colour and exposure settings using the IDS camera U3-3040CP-C-HQ Rev.2.2 and the IDS peak software.

The video sequence / image shows the layer-by-layer PBF-LB/M process with different laser parameters, recorded with the U3-3040CP-C-HQ Rev.2.2 from IDS using the IDS peak software. "Depending on the setting of the industrial camera, various process properties such as material evaporation or the quantity and direction of splashes during the PBF-LB/M can be observed and quantified," says David Kolb, describing the application. "The knowledge gained from this provides us with important information to understand the laser-material interactions of the additive manufacturing process in greater depth and to be able to customise the manufacturing parameters depending on the material or, for example, the component geometry."

To determine the process parameters, cube-shaped components were additively manufactured and the global manufacturing process was analysed using the USB3 uEye CP camera. This made it possible to identify optimum laser parameters with which new types of soft magnetic components for more efficient electric motors of the future can be produced from the difficult-to-process iron-silicon alloy with 6.5 wt.% silicon (FeSi6.5). The stator half-shell made of FeSi6.5 based on this enables ideal adaptation to the special requirements of transverse flux machines thanks to its optimised, three-dimensional magnetic flux guidance. The high electrical resistance of the material and the design freedom of the PBF-LB/M allow a reduction in eddy current losses, increased power density and the integration of additional functions such as cooling structures. Both the complex geometry and the brittle, soft magnetic material FeSi6.5 are almost impossible to produce or process using conventional manufacturing processes and require the use of additive manufacturing technologies.

Additively manufactured soft magnetic stator half-shell of a transverse flux machine made of FeSi6.5 on a construction platform.

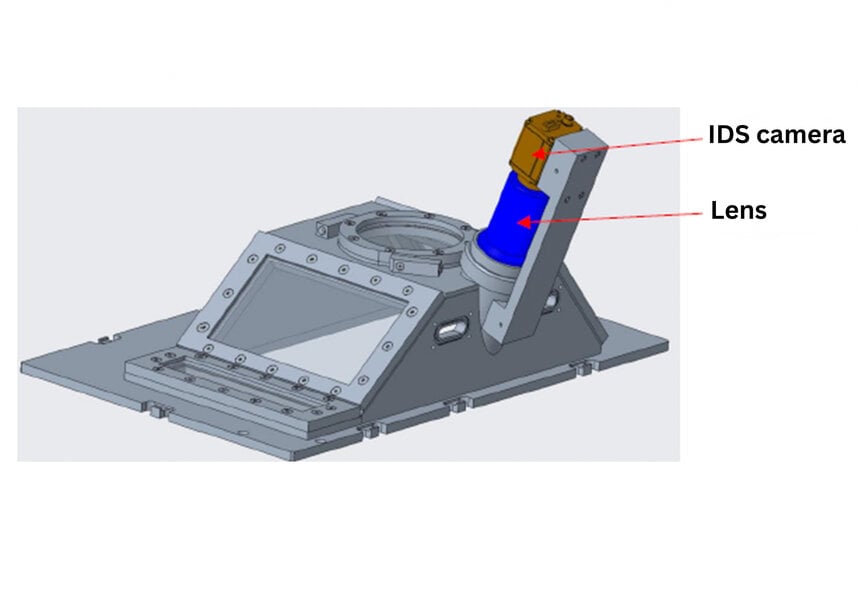

For static, high-resolution observation of powder layers or component layer geometries, on the other hand, the following camera properties are required in particular - in addition to a trigger port for single image recording: The sensor must be able to detect geometric features below 40 µm in order to identify defects in the layers and offer an image field of at least 100 mm × 100 mm and an image ratio that is as square as possible (1:1). This is exactly what the 20.36 megapixel (4512 x 4512 px) industrial camera U3-3990SE Rev.1.2 delivers. With the IMX541, it has a high-performance, extremely high-resolution, large-format 1.1" CMOS sensor from Sony's Pregius S series. The BSI technology ("Back Side Illuminated") used enables smaller pixels (2.74 µm) and a higher resolution, as well as improved quantum efficiency and sensitivity.

"Thanks to the particularly user-friendly and flexibly integrable IDS cameras, the necessary adjustments to the test setup could be implemented quickly and easily so that the USB3 uEye SE can be positioned specifically at a defined angle," explains David Kolb. The near-vertical observation of the individual powder component geometry layers will provide valuable insights into component quality and potential manufacturing defects once the final adjustments have been completed.

In this way, crucial information about the properties of additively manufactured components can be obtained and used specifically to optimise the manufacturing processes.

Design adjustments to the test setup for positioning the IDS camera U3-3990SE-M-GL Rev.1.2 for static observation of the powder component geometry layers.

Outlook

Research in the field of PBF-LB/M is essential for the development and processing of new material alloys and the production of performance-enhancing, sometimes multi-material component geometries. An in-depth understanding of the process helps to minimise defects and realise innovative designs that would not be possible using conventional production methods. The IDS cameras provide in-depth insights into the PBF-LB/M and thus make a valuable contribution to research, development and transfer (R&D&T) - for example in the processing of new material alloys or the production of complex, application-optimised (multi-material) components.

In future, artificial intelligence will be used to automatically analyse the dynamic and static observation of the PBF-LB/M. The aim is to gain an even better understanding of the highly dynamic laser-material interaction - such as the number and trajectory of spatter and the formation of process errors - and to further improve the additive manufacturing process in terms of resource efficiency and sustainability.

Cameras

uEye CP - in industry standard format 29 x 29 mm with patented housing design

Model used: U3-3040CP Rev.2.2

Camera family: uEye CP

uEye SE - "Standard Edition" / All-round industrial camera with universal mounting options

Model used: U3-3990SE-M-GL Rev.1.2

Camera family: uEye SE

Client

The LaserApplicationCentre (LAZ) at Aalen University is affiliated to the Bachelor's degree programme Process Engineering and Management (PEM) and the Research Master's degree programme Advanced Materials and Manufacturing (AMM) and is part of the Aalen School of Applied Photonics (AASAP). The focus is on research topics relating to laser material processing with a particular emphasis on sustainable production technologies. Innovative topics such as additive manufacturing, the modification of surfaces and volumes as well as joining technologies are being researched. Controlled process management, state-of-the-art measurement technology and machine learning methods are used.